China Headquarters

and Manufacturing Center

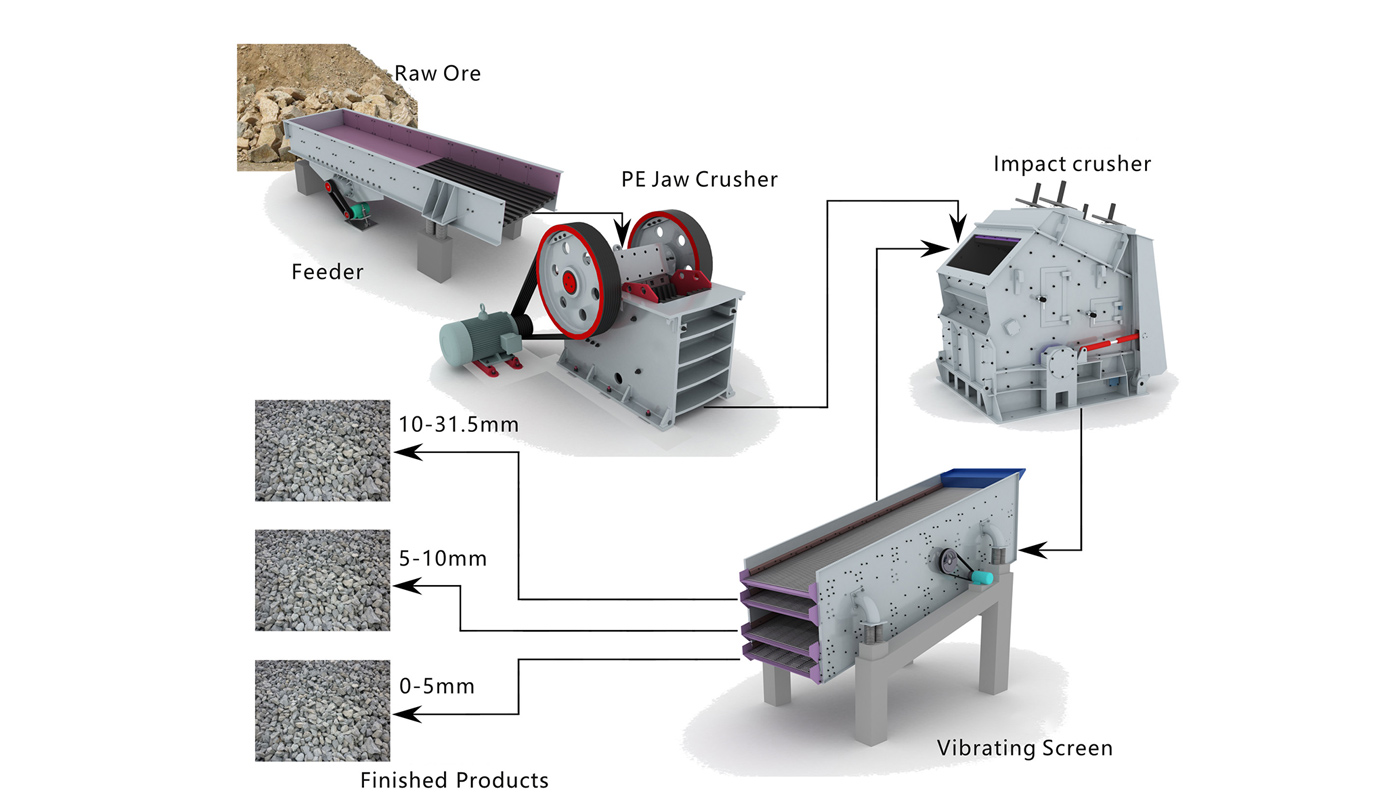

The Nile Machinery Co., Ltd. provides EPC (Engineering, Procurement, and Construction) services for ore machinery projects, including project design, equipment manufacturing,installation, commissioning, and operational maintenance. We specialize in producing and trading crushing equipment, mobile crushing plants, grinding equipment, sand and gravel equipment, gold ore projects, and mineral processing equipment. We have completed numerous EPC projects worldwide, including gold, chrome, and copper ore projects, as well as sand and cement production lines in Africa, Southeast Asia, South America, and the Middle East. Whether the customer only needs one machine or a production line, we will provide services with the attitude that best suits the user's work.

-

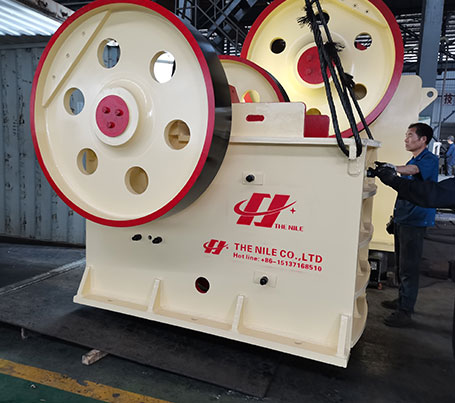

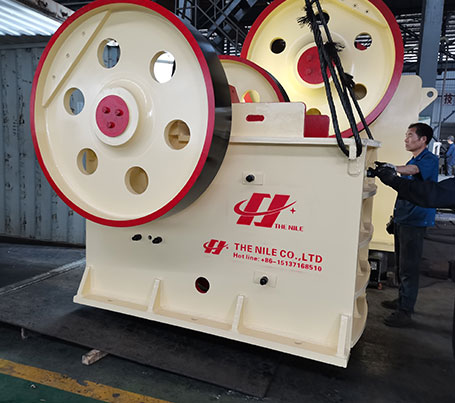

Manufacturing Center

-

Engineer Team

-

Manufacturing Workshop

-

Warehouse for Shipment

-

Warehouse for Spare Parts

-

Logistics Support Team

Kenya Branch

We established a branch and local warehouse in Nairobi, Kenya in 2019, and continue to provide mining machinery, accessories and after-sales services to Kenya and nearby countries.

-

Sudan Branch

We opened up the Sudan gold ore beneficiation market in 2011 and established a Sudan branch in 2016 to provide services to Sudan and neighboring countries.

-

Tanzania Mineral Laboratory

We prepared a mineral processing laboratory in Tanzania in 2024 with the aim of providing local and African users with ore sample processing, microscopic identification, phase anal-ysis, film making, concentration and dehydration, filtration and drying, and various mineral processing process experiments.