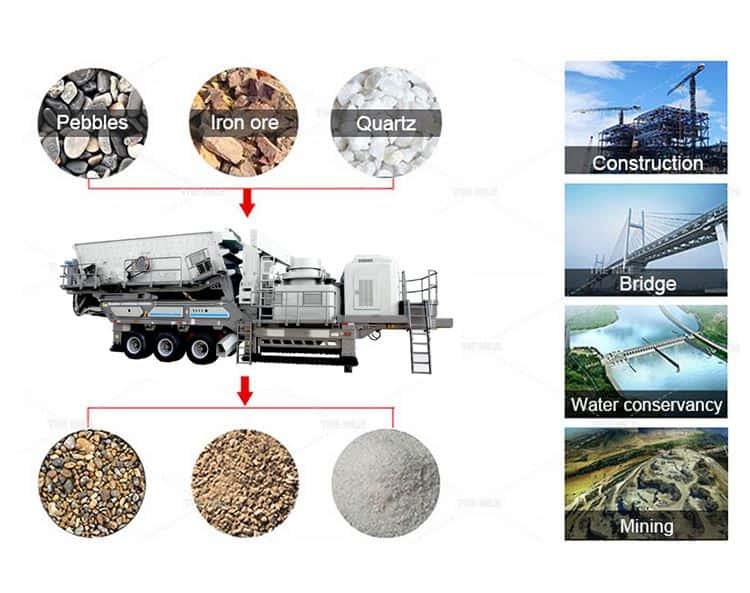

The mobile cone crusher station is suitable for the processing of various hard materials, such as limestone, bluestone, granite, river pebble, limestone, basalt, etc. It can be used with different series of cone crushers for materials of different properties. It is not only applicable to Strong and high production efficiency.

Product introduction:

The mobile cone stone crushing plant is mainly used for the processing of materials that need to be moved frequently, such as chemicals, building materials, water, and electricity. Especially it is widely used in mountain roads, railways, and other operations. Users can use a variety of configurations according to the different requirements of the finished materials to perform operations.

The working principle of the mobile rock crushing plant equipment:

When the mobile stone cone crushing station machine is operating, the stones that meet the feed size are uniformly transported to the cone crusher by the feeder. After the cone crusher is initially crushed, the screening control is carried out. Only the qualified stones can enter the next processing process. , The closed-circuit system can realize the cyclic crushing of materials. The finished materials are output by the conveyor for continuous crushing operations. The entire crushing process is smooth and efficient, and the materials flow at high speed between various equipment.

Advantages of mobile cone crushing plant for sale

1. The mobile cone crushing plant machinery is flexible and convenient, with good mobility and low transportation cost.

2. The mobile rock cone crushing station can be used independently, and it can also provide a more flexible process configuration according to the customer's requirements for the material type and product in the process, to meet the user's mobile crushing, mobile screening, and other requirements.

3. The mobile cone crushing station manufacturer integrates material receiving, crushing, conveying, and other process equipment, which reduces the cumbersome procedures and man-hour consumption of infrastructure installation.

4. Low energy consumption and low dust pollution

Our service:

Pre-sale service:

(1) Professional technicians provide customers with suggestions for model selection.

(2) Design and manufacture machines according to customers' special requirements.

After-sales service:

(1)) Arrange technicians to guide the installation

(2) If your machine is out of warranty, you can buy spare parts from us at the best price.

(3) Engineers can repair machines overseas

| Mobile coneCrushering plant | NS1848PSG0917 | NS1860PSG1324 | NS1848HD100 | NS1860HD200 | NS2160HP300 | |

| Crusher plant size | Transport Length(mm) | 12600 | 13800 | 12600 | 14300 | 16850 |

| Transport Width(mm) | 3000 | 3000 | 3000 | 3000 | 3000 | |

| Transport Height(mm) | 4500 | 4500 | 4500 | 4500 | 4500 | |

| impact crusher | Feed size(mm) | 100 | 150 | 200 | 300 | 150 |

| Capacity(t/h) | 60-120 | 120-200 | 80-180 | 120-280 | 180-300 | |

| Model | PSG0917 | PSG1324 | HD100 | HD200 | HPY300 | |

| Screen type | 3YK1848 | 3YK1860 | 3YK1848 | 3YK1860 | 3YK2160 | |

| Conveyor belt | B800*7.5m | B800*8.5m | B800*8.5m | B800*8.5m | B1000*8.5m | |