Processing Materials: Ball mill is widely applied for grinding limestone, quartz, aluminum slag, iron ore, copper ore, gold ore, bauxite, calcite, coal gangue, gypsum, slag, fly ash, etc.

Applied Field: Ball mill is usually used in the field of cement, silicate products, new building materials, refractories, fertilizers, black and non-ferrous metal mineral processing and glass ceramics, and others.

Technical Parameters of Ball Mill

| Model | Ball weight (t) | Feed size(мм) | Output | Motor power (kw) | Weight |

| Size | (T) | ||||

| mm) | |||||

| Ф900×1200 | 1 | ≤20 | 0.074-0.4 | 18.5 | 4 |

| Ф900×1800 | 1.5 | ≤20 | 0.074-0.4 | 22 | 4.8 |

| Ф1200×2400 | 3.5 | ≤25 | 0.074-0.4 | 30 | 9.5 |

| Ф1200×4500 | 5 | ≤25 | 0.074-0.4 | 45 | 13.1 |

| Ф1500×3000 | 7 | ≤25 | 0.074-0.4 | 75 | 16 |

| Ф1500×4500 | 10 | ≤25 | 0.074-0.4 | 110 | 19 |

| Ф1830×3000 | 10 | ≤25 | 0.074-0.4 | 130 | 25 |

| Ф1830×3600 | 12 | ≤25 | 0.074-0.4 | 155 | 32 |

| Ф1830×4500 | 15 | ≤25 | 0.074-0.4 | 155 | 33.7 |

| Ф2100×3600 | 22.5 | ≤25 | 0.074-0.4 | 210 | 45.8 |

| Ф2200×4500 | 28 | ≤25 | 0.074-0.4 | 280 | 46.5 |

| Ф2400×4500 | 30 | ≤25 | 0.074-0.4 | 380 | 65 |

| Ф2700×4500 | 43 | ≤25 | 0.074-0.4 | 480 | 97 |

| Ф3200×4500 | 59 | ≤25 | 0.074-0.4 | 630 | 156.5 |

| Ф3600×4500 | 75 | ≤25 | 0.074-0.4 | 1000 | 162 |

Product Description of Ball Mill

The ball mill is the key equipment for grinding materials after crushing, which is equipped with a certain number of steel balls as grinding media in its cylinder. Ball mill machine is suitable for grinding various ores and plays an important role in mineral processing, building materials, and the chemical industry. It's really easy for the installation of ball mill without requiring any special maintenance. The main bearing of ball mill grinding machine adopts a large diameter double row self-aligning roller bearing instead of the original sliding bearing, which reduces friction and energy consumption and makes the mill easy to start.

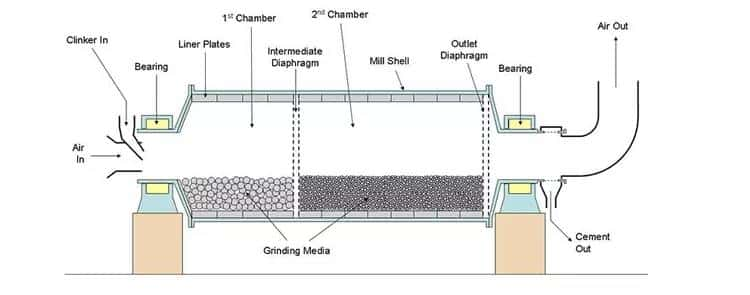

Working Principle of Ball Mill

The ball mill is a horizontal cylindrical rotation device with driving by edge gear. There are two cavities and grids for the ball mill plant. The material enters the first cavity through the feeding port. Inside the first cavity, there are stage liners, ripple liners as well as various kinds of steel balls. The shell rotation produces eccentricity and makes the grinding ball reach a certain height and then falls due to gravity, which will impact and grind the material. After the primary grinding in the first cavity, the material goes into the second cavity through the segregate screen. In the second cavity, there are fiat liners and steel balls. After the secondary grinding, the material is discharged through the discharge screen of the ball mill.

Packing&Shipping

Standard packing in export container

Customer Cases

FAQ

Q1: How is the quality of your products?

A: We have been approved of ISO, CE, BV, and always produce our products strictly according to international standards. We do strict inspection in every production stage, all the machines we sell are under warranty.

Q2: What about the order lead time?

A: We have big productivity, the order lead time is only 12-15 days.

Q3: What Delivery terms do you accept?

A: We accept FOB,CIF,CFR,FCA,CPT,CIP.

No more→

| Model | Ball weight (t) | Feed size(мм) | Output | Motor power (kw) | Weight |

| Size | (T) | ||||

| mm) | |||||

| Ф900×1200 | 1 | ≤20 | 0.074-0.4 | 18.5 | 4 |

| Ф900×1800 | 1.5 | ≤20 | 0.074-0.4 | 22 | 4.8 |

| Ф1200×2400 | 3.5 | ≤25 | 0.074-0.4 | 30 | 9.5 |

| Ф1200×4500 | 5 | ≤25 | 0.074-0.4 | 45 | 13.1 |

| Ф1500×3000 | 7 | ≤25 | 0.074-0.4 | 75 | 16 |

| Ф1500×4500 | 10 | ≤25 | 0.074-0.4 | 110 | 19 |

| Ф1830×3000 | 10 | ≤25 | 0.074-0.4 | 130 | 25 |

| Ф1830×3600 | 12 | ≤25 | 0.074-0.4 | 155 | 32 |

| Ф1830×4500 | 15 | ≤25 | 0.074-0.4 | 155 | 33.7 |

| Ф2100×3600 | 22.5 | ≤25 | 0.074-0.4 | 210 | 45.8 |

| Ф2200×4500 | 28 | ≤25 | 0.074-0.4 | 280 | 46.5 |

| Ф2400×4500 | 30 | ≤25 | 0.074-0.4 | 380 | 65 |

| Ф2700×4500 | 43 | ≤25 | 0.074-0.4 | 480 | 97 |

| Ф3200×4500 | 59 | ≤25 | 0.074-0.4 | 630 | 156.5 |

| Ф3600×4500 | 75 | ≤25 | 0.074-0.4 | 1000 | 162 |