The vibrating screen machine for sale has an elliptical vibration track, which is a multi-layer, high-efficiency new vibrating screen. The function of each layer of the circular vibrating screen is different, not only the processing capacity is large, but also it is strong and durable.

Product description:

Circular vibrating screen equipment is indispensable screening equipment in the production line. It not only has a strong excitation force, low noise, and long service life, it is widely used in the screening of coal, limestone, gravel, gravel, metal and nonmetal ores, and other materials.

The working principle of vibrating screen machine for sale:

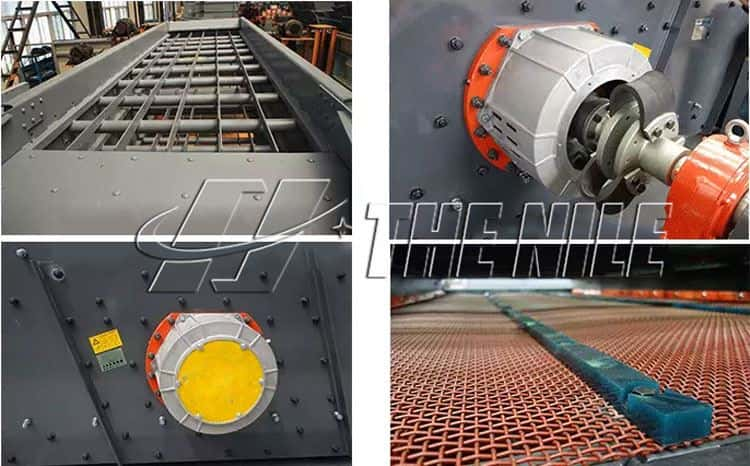

The motor drives the eccentric block of the exciter to rotate through the triangle belt, and the centrifugal inertia force generated on the exciter drives the screen box to vibrate. By changing the eccentric weight of the exciter, different amplitudes can be obtained. The material meets the screen surface and small particles Through the screen, classification is realized.

Features of mine vibrating screen

1. The vibration exciter of the circular vibrating screen for sale adopts a block eccentric structure, which is not only convenient for maintenance during use but also increases the effective screening area of the circular vibrating screen.

2. The vibrating screen machine for sale uses rubber vibration springs, low noise, stable and reliable

3. The circular stone vibrating screen has high working efficiency and less material blockage.

4. The intermediate transition bearing seat is added to the transmission part of the circular vibrating screen machine. The application of the intermediate transition bearing seat effectively protects the motor and prolongs the service life of the motor.

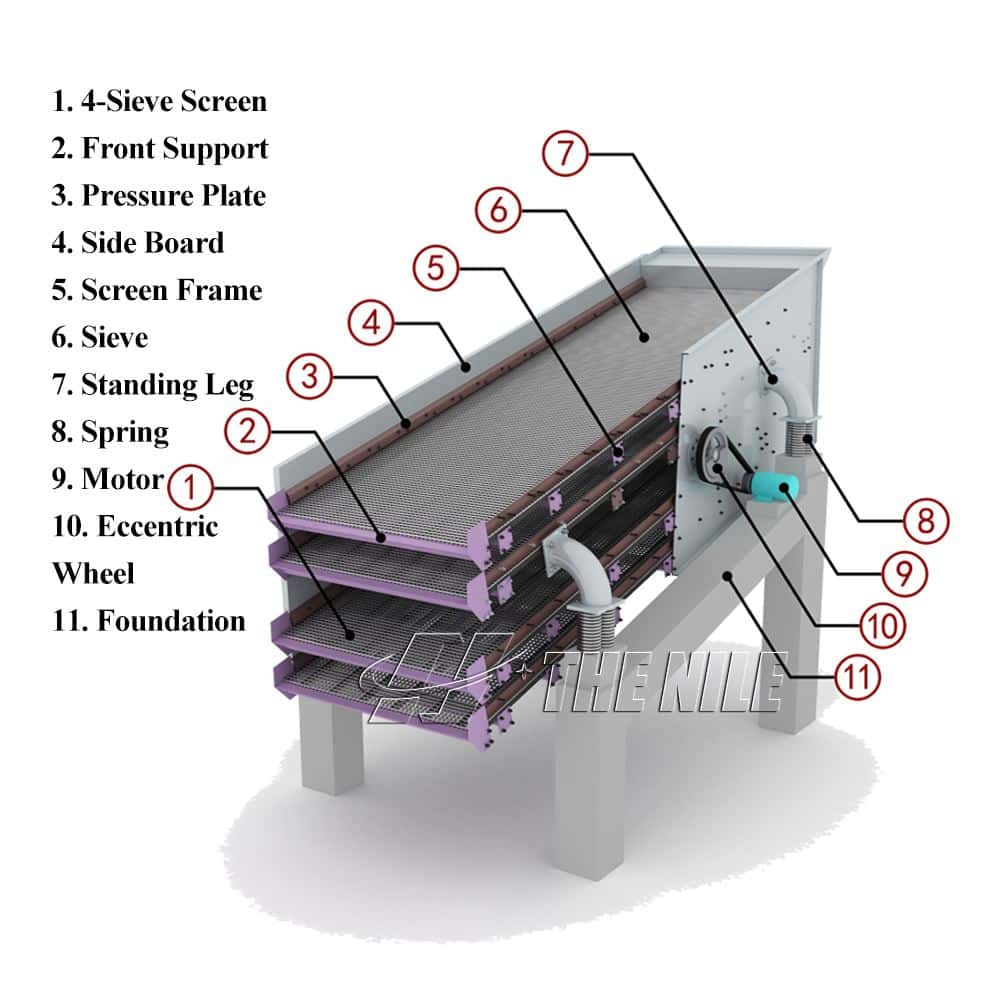

The structure of the circular vibrating screen machine for stone

YK series circular vibrating screen is mainly composed of a screen box, screen mesh, vibrator, and damping spring.

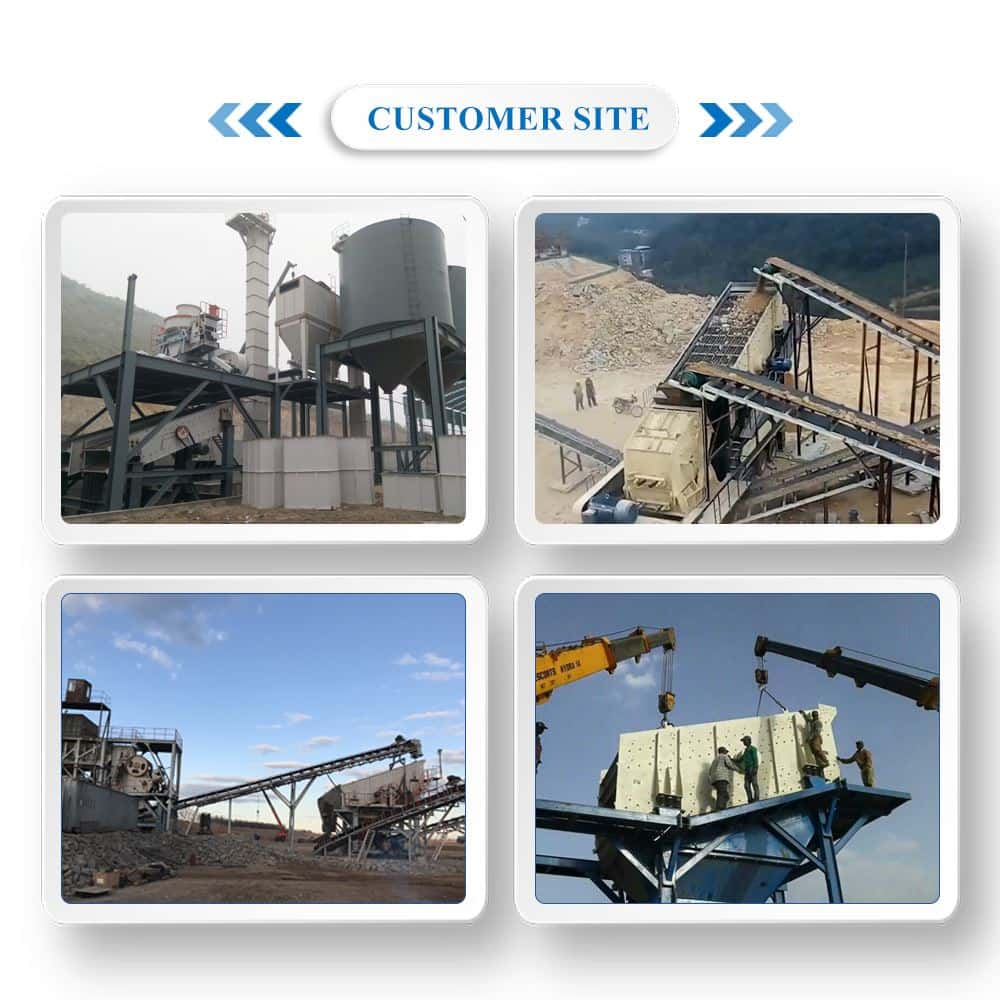

Customer case

Company strength

The Nile Machinery Equipment Co., Ltd. is a metallurgical machinery professional machinery factory that specializes in mining equipment research and development, manufacturing, sales, and provides professional mining processing plant workflow design, plant installation, equipment maintenance, and mineral processing technical guidance services. Our products are exported to Africa, Nigeria, Zambia, Zimbabwe, Uganda, Mozambique, South America, the Middle East, and many other countries and regions. At present, we have established our own overseas warehouses in Sudan and Kenya, and we also have our offices in most parts of Africa. You can observe the machinery up close and buy directly, saving transportation costs and time.

Our workshop

Customer visiting

The product packaging

Project case: 600t/h limestone crushed stone production line

Material: Limestone

Output: 600 t/h

Configuration equipment: vibrating feeder, jaw crusher, impact crusher, high-efficiency fine crusher, vibrating screen, etc.

client feedback

The crushed stone production line designed by the Nile has a high degree of automation. The complete production line requires almost no manual operation except for the startup and shutdown of the equipment and daily maintenance. In addition, the production line they configure has high production efficiency, and the finished stones have a uniform particle size, which brings us high profits. Looking forward to the next cooperation with the Nile!

| Model | Screen mesh | Layers | Max Feed size | Capacity | Screen Specification | Weight |

| (mm) | (mm) | (m³/h) | (mm) | (kg) | ||

| 2YK1237 | 2-50 | 2 | 200 | 25-50 | 1200×3700 | 4900 |

| 3YK1237 | 2-50 | 3 | 200 | 30-60 | 1200×3700 | 5200 |

| 4YK1237 | 2-50 | 4 | 200 | 30-60 | 1200×3700 | 5300 |

| 2YK1548 | 2-50 | 2 | 200 | 45-90 | 1500×4800 | 6300 |

| 3YK1548 | 2-50 | 3 | 200 | 45-90 | 1500×4800 | 6500 |

| 4YK1548 | 2-50 | 4 | 200 | 45-90 | 1500×4800 | 6600 |

| 2YK1848 | 2-50 | 2 | 200 | 55-110 | 1800×4500 | 6900 |

| 3YK1848 | 2-50 | 3 | 200 | 55-110 | 1800×4500 | 7200 |

| 4YK1848 | 2-50 | 4 | 200 | 55-110 | 1800×4500 | 7500 |

| 2YK1860 | 2-50 | 2 | 200 | 65-130 | 1800×6000 | 7100 |

| 3YK1860 | 2-50 | 3 | 200 | 65-130 | 1800×6000 | 7400 |

| 4YK1860 | 2-50 | 4 | 200 | 65-130 | 1800×6000 | 7700 |

| 2YK2160 | 2-50 | 2 | 200 | 80-160 | 2100×6000 | 11200 |

| 3YK2160 | 2-50 | 3 | 200 | 90-180 | 2100×6000 | 12400 |

| 4YK2160 | 2-50 | 4 | 200 | 90-180 | 2100×6000 | 15100 |

| 2YK2460 | 2-50 | 2 | 200 | 150-300 | 2400×6000 | 13500 |

| 3YK2460 | 2-50 | 3 | 200 | 180-360 | 2400×6000 | 13600 |

| 4YK2460 | 2-50 | 4 | 200 | 180-360 | 2400×6000 | 14400 |