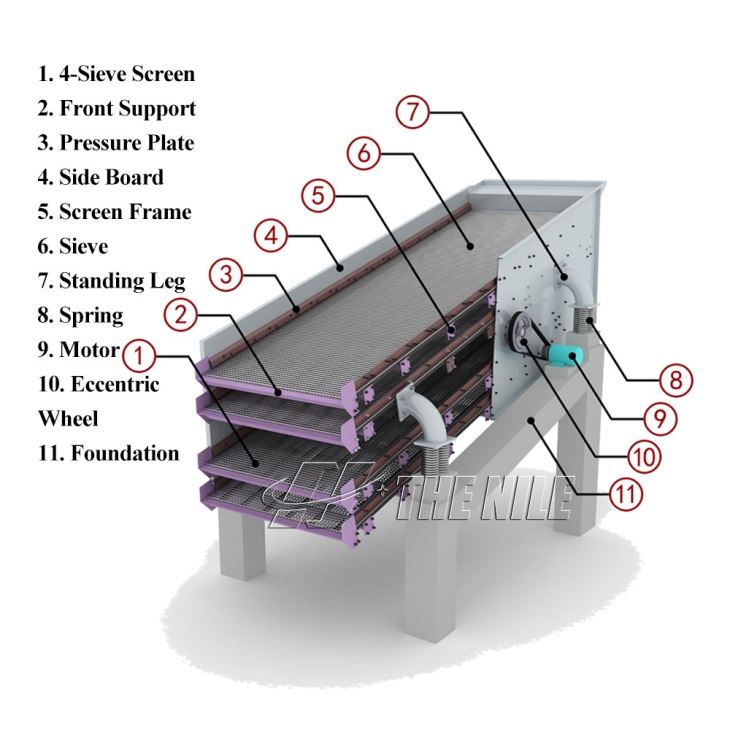

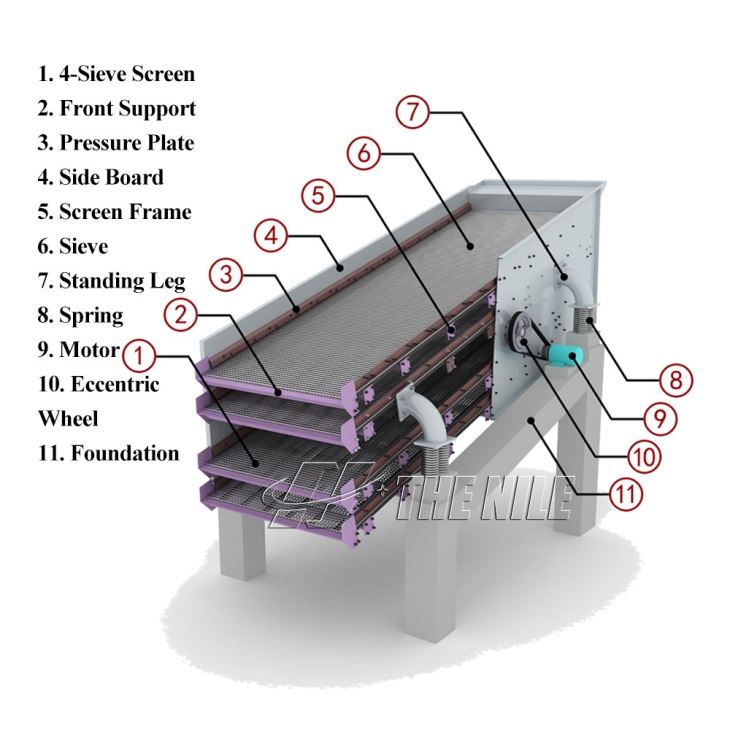

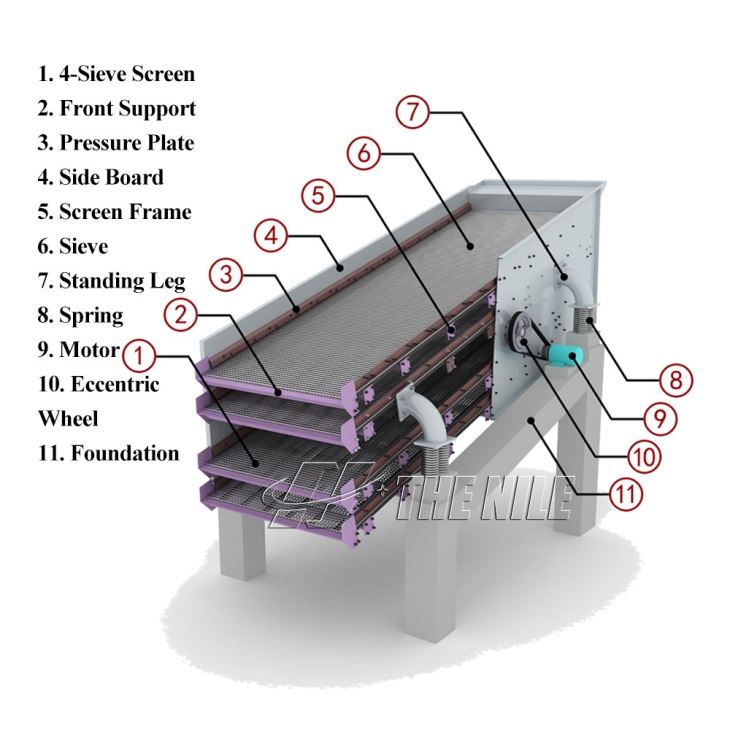

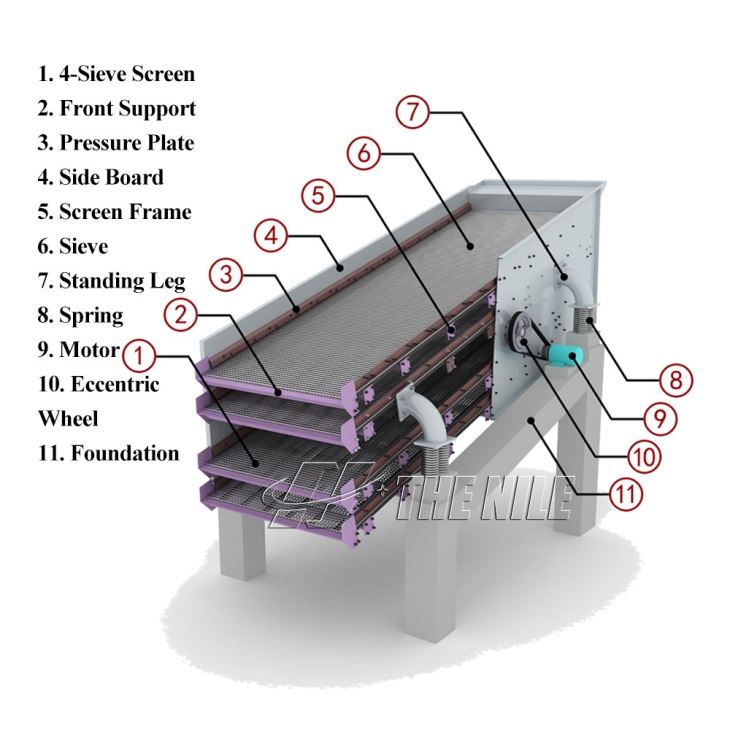

The vibrating Screen has a variety of screening specifications, up to four layers, and each layer has different functions. It has the advantages of large processing capacity, sturdiness and durability, and reliable structure.

Product description:

The circular vibrating screen equipment adopts a cylindrical eccentric shaft vibration exciter and an offset block to adjust the amplitude. The material screen has a long flow line and a variety of screening specifications. It has a strong excitation force, reliable structure, high screening efficiency, low vibration and noise, sturdiness and durability, and maintenance. Convenient, safe to use, and other advantages. Designed specifically for quarry screens, circular motion vibrating screens can also be used for grading products in the building materials, coal, chemical, mineral processing, power, chemical, and other sectors.

Application fields of circular vibrating screen machine:

Circular vibrating screens are widely used in quarries, dry mortar, machine-made sand, power plant desulfurization, quartz sand, etc. It can also be used for screening materials such as cobblestone, granite, basalt, iron ore, limestone, calcite, quartz, and diabase.

The working principle of mining circular vibrating screen:

The motor makes the eccentric block of the exciter rotate at a high speed through the V-belt. Running the eccentric block produces a large centrifugal force, which stimulates the circular motion amplitude screen box to make a circular motion. The material on the screen box produces momentum when the screen surface is inclined, resulting in continuous casting movement. When the material meets the screen surface, the small particles pass through the screen to achieve classification.

Features of circular vibrating screen machine for stone:

1. There are many screening specifications and a wide range of applications.

2. The eccentric block is used as the exciting force, which has a strong exciting force and high screening efficiency.

3. The screen beam and the screen box of the circular vibrating screen for sale are connected by high-strength bolts without welding, which is stable and durable.

4. The structure of small amplitude, high frequency, and high inclination makes the vibrating screen have the advantages of high efficiency, low noise, long life, low energy consumption, and large processing capacity.

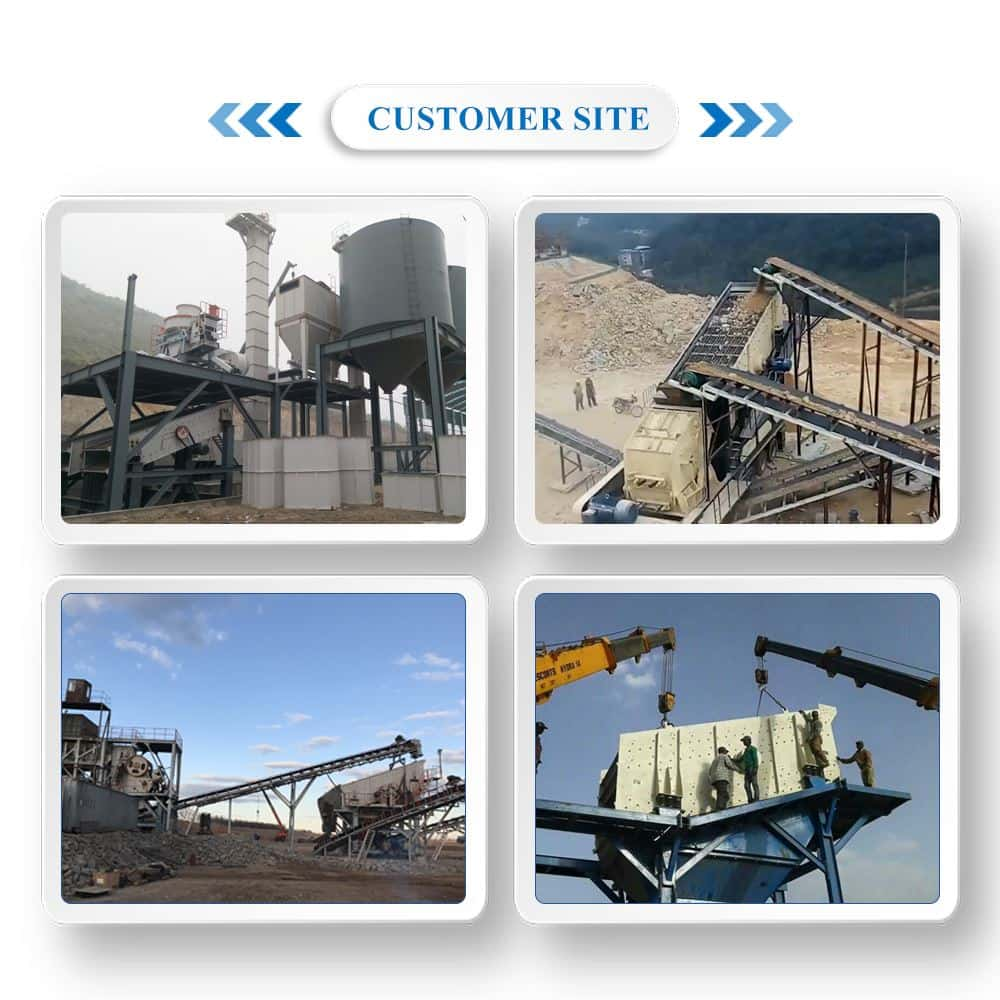

Company strength

The Nile Machinery Equipment Co., Ltd. is a metallurgical machinery professional machinery factory that specializes in mining equipment research and development, manufacturing, sales, and provides professional mining processing plant workflow design, plant installation, equipment maintenance, and mineral processing technical guidance services. Our products are exported to Africa, Nigeria, Zambia, Zimbabwe, Uganda, Mozambique, South America, the Middle East, and many other countries and regions. We are committed to creating high-quality and efficient crushing and screening equipment and always adhere to the purpose of high-quality machines and the original intention of the customer first.

| Model | Screen mesh | Layers | Max Feed size | Capacity | Screen Specification | Weight |

| (mm) | (mm) | (m³/h) | (mm) | (kg) | ||

| 2YK1237 | 2-50 | 2 | 200 | 25-50 | 1200×3700 | 4900 |

| 3YK1237 | 2-50 | 3 | 200 | 30-60 | 1200×3700 | 5200 |

| 4YK1237 | 2-50 | 4 | 200 | 30-60 | 1200×3700 | 5300 |

| 2YK1548 | 2-50 | 2 | 200 | 45-90 | 1500×4800 | 6300 |

| 3YK1548 | 2-50 | 3 | 200 | 45-90 | 1500×4800 | 6500 |

| 4YK1548 | 2-50 | 4 | 200 | 45-90 | 1500×4800 | 6600 |

| 2YK1848 | 2-50 | 2 | 200 | 55-110 | 1800×4500 | 6900 |

| 3YK1848 | 2-50 | 3 | 200 | 55-110 | 1800×4500 | 7200 |

| 4YK1848 | 2-50 | 4 | 200 | 55-110 | 1800×4500 | 7500 |

| 2YK1860 | 2-50 | 2 | 200 | 65-130 | 1800×6000 | 7100 |

| 3YK1860 | 2-50 | 3 | 200 | 65-130 | 1800×6000 | 7400 |

| 4YK1860 | 2-50 | 4 | 200 | 65-130 | 1800×6000 | 7700 |

| 2YK2160 | 2-50 | 2 | 200 | 80-160 | 2100×6000 | 11200 |

| 3YK2160 | 2-50 | 3 | 200 | 90-180 | 2100×6000 | 12400 |

| 4YK2160 | 2-50 | 4 | 200 | 90-180 | 2100×6000 | 15100 |

| 2YK2460 | 2-50 | 2 | 200 | 150-300 | 2400×6000 | 13500 |

| 3YK2460 | 2-50 | 3 | 200 | 180-360 | 2400×6000 | 13600 |

| 4YK2460 | 2-50 | 4 | 200 | 180-360 | 2400×6000 | 14400 |