Applied Field: Circular vibrating screen separators are commonly used for screening various soft and medium-hard ores, construction waste, tailings, steel slag, which are widely suitable for screening sand and stone in quarries, product classification in coal preparation, mineral processing, building materials, electric power, and chemical industries.

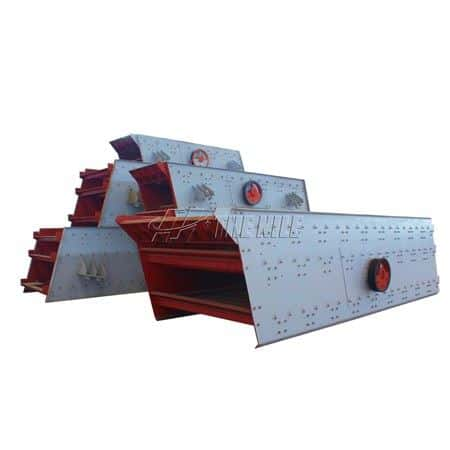

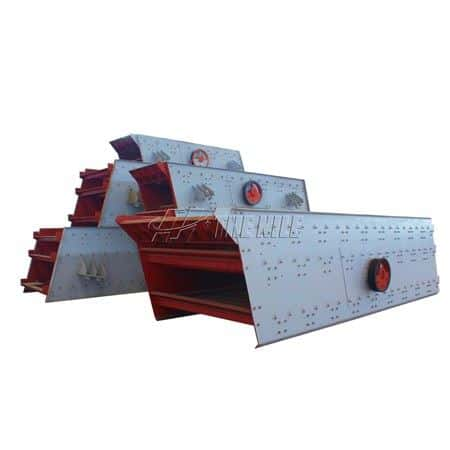

The internal structure of Circular Vibrating Screen Separators

The circular vibrating screen separators are mainly composed of screen box, screen, suspension (or support) device, motor, vibrator, and damping spring. The motor drives the main shaft of the vibrator to rotate through the triangle belt. Due to the centrifugal inertia force of the unbalanced weight on the vibrator, the screen box is vibrated. Different amplitudes can be obtained by changing the eccentric weight of the vibrator.

Operation Points of Circular Vibrating Screen Separators

1.The operator should read the on-duty record and conduct a general inspection of the equipment before working. Check the tension degree of the triangle belt, the oil level in the vibrator, the tension of the screen surface, the fastening of bolts in each part, and the damage of the screen surface.

2.The start-up of the vibrating screen should follow the sequence of the processing system.

3.When the vibrating screen is in operation, visually and auditorily check the working conditions of the exciter and the screen box. After the shaker stops, touch the bearing cover by hand to check the bearing temperature rise.

4.The shutdown of circular vibrating screen separators should conform to the sequence of the process system. Except for special requirements, it is forbidden to continue feeding to the screen after stopping with the material.

5. Record the technical status and faults of the screen on duty during shift handover. The damage category of parts and the date of oil filling and changing of exciter shall be indicated in the record of circular vibrating screen separators.

Technical Parameters of Circular Vibrating Screen Separators

Model | Layers | Max Feed | Capacity | Screen Specification | Weight | Dimension |

2YK1225 | 2 | 400 | 8-60 | 1200×2500 | 3500 | 2930×1860×870 |

3YK1225 | 3 | 400 | 10-70 | 1200×2500 | 3850 | 3070×1860×1210 |

2YK1230 | 2 | 400 | 12-78 | 1200×3000 | 4200 | 3430×1860×870 |

3YK1230 | 3 | 400 | 13-80 | 1200×3700 | 4600 | 3570×1860×1210 |

2YK1237 | 2 | 400 | 15-86 | 1200×3700 | 4600 | 4050×1860×870 |

3YK1237 | 3 | 400 | 16-90 | 1500×3500 | 5200 | 4270×1860×1210 |

2YK1535 | 2 | 400 | 20-125 | 1500×3500 | 5890 | 4120×2210×1230 |

3YK1535 | 3 | 400 | 21-125 | 1500×3500 | 6700 | 4360×2210×1610 |

2YK1545 | 2 | 400 | 22-150 | 1500×4500 | 6330 | 5120×2210×1230 |

3YK1545 | 3 | 400 | 22-150 | 1500×4500 | 6800 | 5360×2210×1610 |

4YK1545 | 4 | 400 | 22-155 | 1500×4500 | 7800 | 5930×2210×2060 |

2YK1548 | 2 | 400 | 22.5-162 | 1500×4800 | 6980 | 5420×2210×1230 |

3YK1548 | 3 | 400 | 22.5-162 | 1500×4800 | 7700 | 5660×2210×1610 |

4YK1548 | 4 | 400 | 22.5-162 | 1500×4800 | 8700 | 6230×2210×2060 |

2YK1848 | 2 | 400 | 25-206 | 1800×4800 | 9080 | 5420×2550×1420 |

3YK1848 | 3 | 400 | 32-276 | 1800×4800 | 9600 | 5660×2550×1780 |

4YK1848 | 4 | 400 | 32-285 | 1800×4800 | 11100 | 6290×2550×2160 |

2YK1854 | 2 | 400 | 32-312 | 1800×5400 | 10150 | 5960×2550×1420 |

3YK1854 | 3 | 400 | 32-312 | 1800×5400 | 10840 | 6260×2550×1780 |

4YK1854 | 4 | 400 | 32-336 | 1800×5400 | 12840 | 6830×2550×2160 |

2YK2160 | 2 | 400 | 50-475 | 2100×2600 | 11780 | 6720×2840×1530 |

3YK2160 | 3 | 400 | 50-475 | 2100×2600 | 12800 | 7030×2840×1910 |

4YK2160 | 4 | 400 | 50-497 | 2100×2600 | 14800 | 7300×2840×2380 |

2YK2460 | 2 | 400 | 65-550 | 2400×6000 | 15600 | 7020×3140×1530 |

3YK2460 | 3 | 400 | 70-620 | 2400×6000 | 17600 | 7300×3140×1910 |

4YK2460 | 4 | 400 | 80-680 | 2400×6000 | 19600 | 7600×3140×2380 |

2YK3072 | 2 | 400 | 200-700 | 3000×7200 | 23600 | 7200×4520×4184 |

3YK3072 | 3 | 400 | 230-800 | 3000×7200 | 25500 | 7200×4520×4684 |