The linear vibrating screen is used for screening and classifying powdery and granular materials, which can be widely used in plastics, abrasives, chemicals, pharmaceuticals, building materials, carbon, chemical fertilizers and other industries.

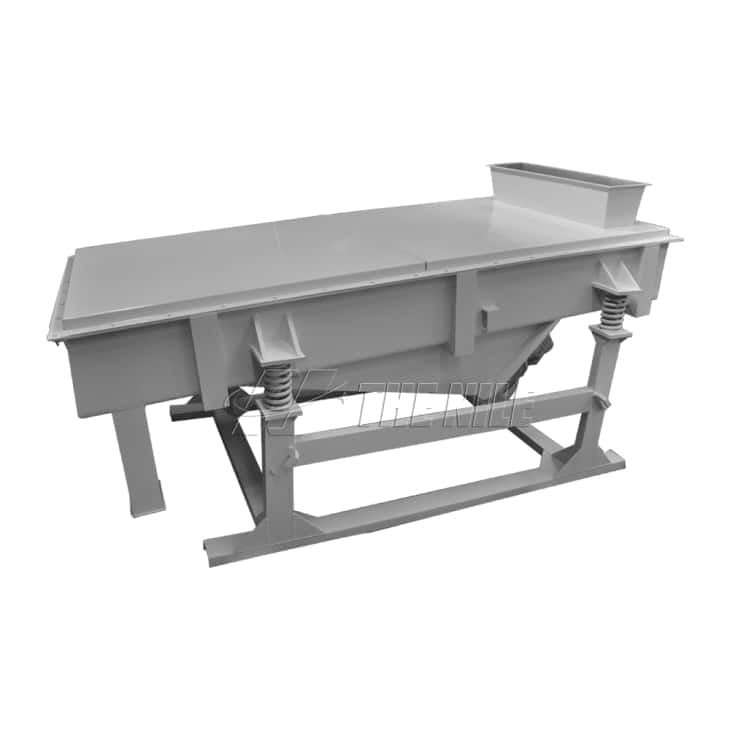

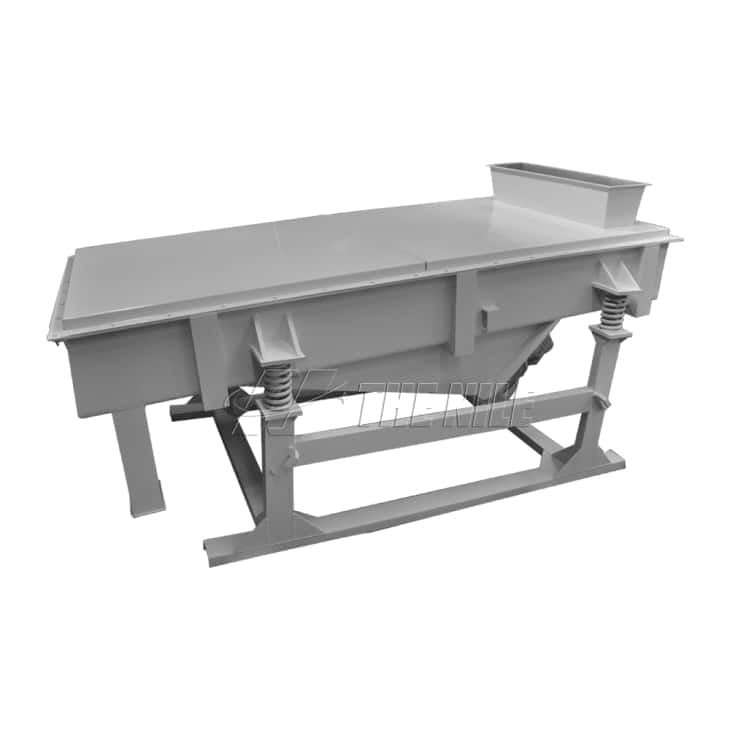

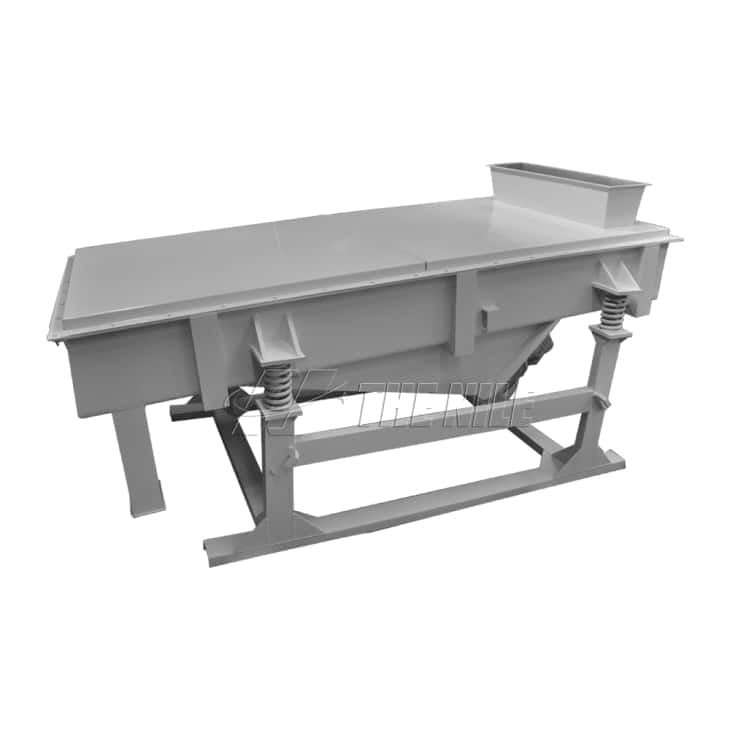

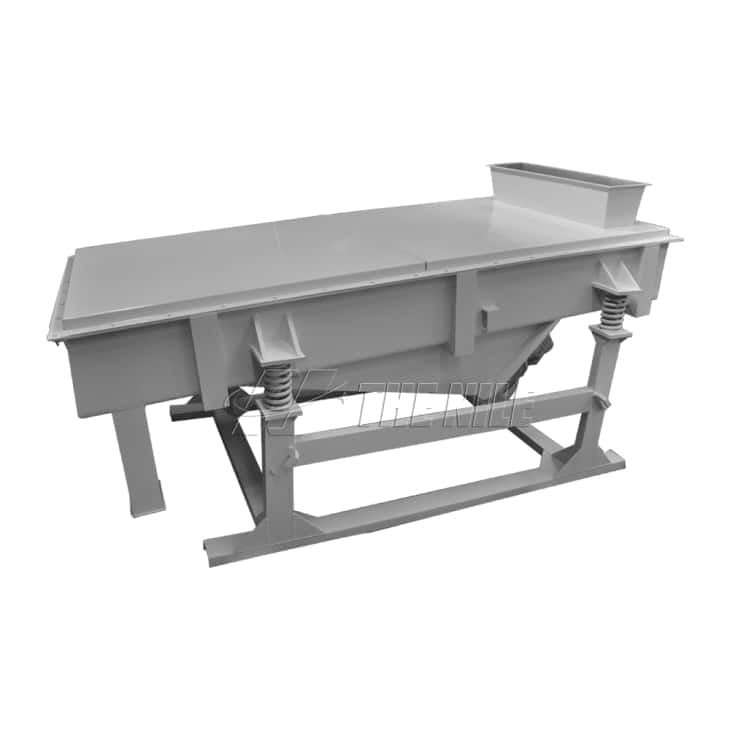

Product Description of Linear Vibrating Screen

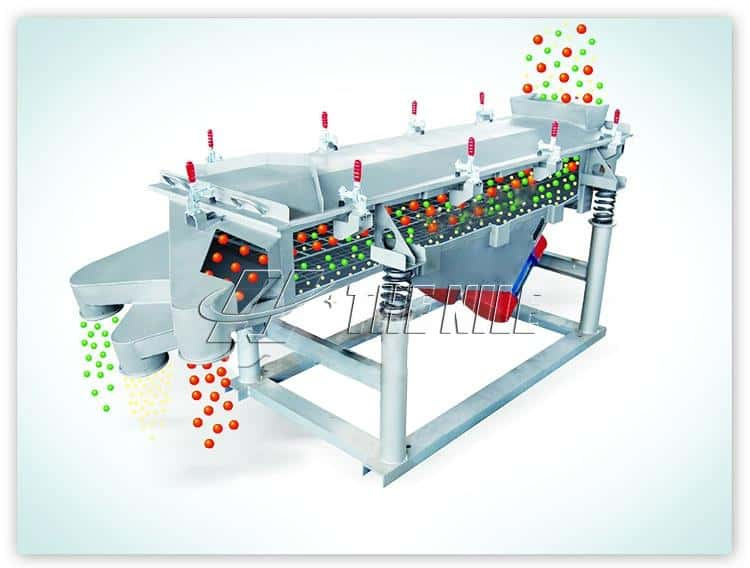

The Linear Vibrating Screen is a kind of standard and universal screening equipment. It consists of a screen frame, supporting device, driving device, vibration, and other parts. The Linear Vibrating Screen uses vibration motor excitation as the source of vibration power so that the material is thrown up on the screen and moves forward linearly. Then the material enters the feed port of the screening machine evenly from the feeder and produces a multilayer screen with several specifications.

Product Description of Linear Vibrating Screen

The Linear Vibrating Screen is a kind of standard and universal screening equipment. It consists of a screen frame, supporting device, driving device, vibration, and other parts. The Linear Vibrating Screen uses vibration motor excitation as the source of vibration power so that the material is thrown up on the screen and moves forward linearly. Then the material enters the feed port of the screening machine evenly from the feeder and produces a multilayer screen with several specifications.

Advantages of Linear Vibrating Screen 1. Linear Vibrating Screen has the prominent features of low energy consumption, high output, simple structure, easy maintenance, a high degree of automation, simple operation, durability as well as highly cost-effective, and is more suitable for assembly line operations. 2. With two vibrating motors mounted on both sides of the machine body, or mounted on the bottom base of the machine body, which makes the materials running a straight trace on the sieve to finish the screening work. 3. All contact parts are made of stainless steel and fully sealed to ensure purity and no dust. |

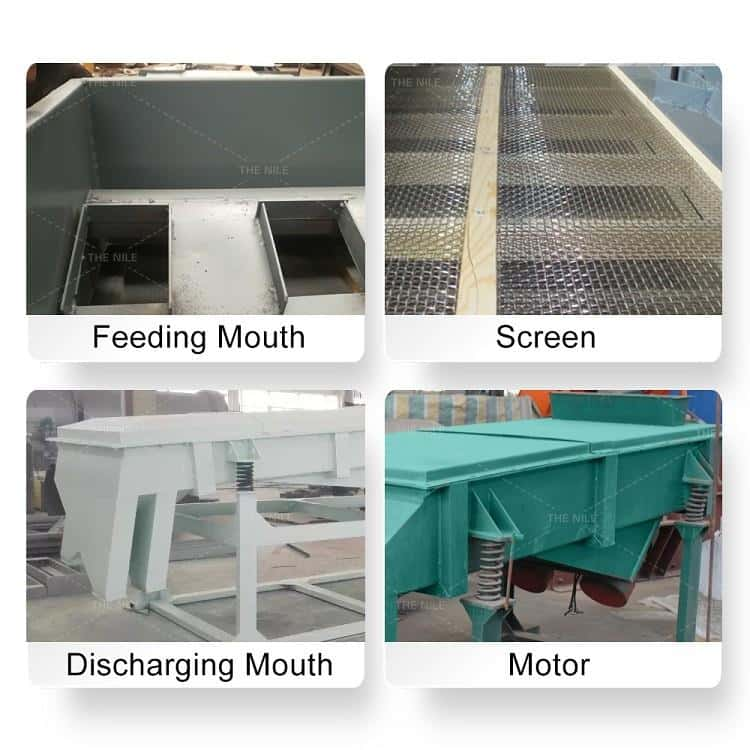

Details ofLinear Vibrating Screen

←No more

Model | Dimension | Input Size | Inclination | Amplitude | Layer | Power |

Szf520 | 500×2000 | 0.074~10 | 0°~7° | 4~8 | 1~5 | 2×(0.4~0.75) |

Szf525 | 500×2500 | 2×(0.4~0.75) | ||||

Szf530 | 500×3000 | 2×(0.75~1.1) | ||||

Szf535 | 500×3500 | 2×(0.75~1.1) | ||||

Szf1020 | 1000×2000 | 2×(0.75~1.5) | ||||

Szf1025 | 1000×2500 | 2×(1.1~1.5) | ||||

Szf1030 | 1000×3000 | 2×(1.5~1.8) | ||||

Szf1035 | 1000×3500 | 2×(1.5~2.2) | ||||

Szf1040 | 1000×4000 | 2×(1.5~2.2) | ||||

Szf1225 | 1200×2500 | 2×(1.5~2.2) | ||||

Szf1230 | 1200×3000 | 2×(1.8~3) | ||||

Szf1235 | 1200×3500 | 2×(1.8~3) | ||||

Szf1530 | 1500×3000 | 2×(2.2~3) | ||||

Szf1535 | 1500×3500 | 2×(2.2~3) | ||||

Szf1540 | 1500×4000 | 2×(2.2~4) |