High efficiency pulp thickener is a continuous working thickening and clarification equipment, mainly used for the dewatering of refined and tailings slurry in wet beneficiation operations. It is also widely used for the concentration and purification of solid slurries such as coal, iron, and steel, chemical industry, building materials, water source, and sewage treatment.

Product introduction:

The pulp thickener machine is an important equipment to increase the concentration of the slurry and obtain the appropriate concentration in the production process. It is generally divided into two types: central transmission and weekly transmission. Pulp thickeners are suitable for the dewatering of concentrates and tailings in concentrators and are widely used in metallurgy, chemical, coal, non-metallic mineral processing, environmental protection, and other industries.

Working principle of thickener

Before entering the high-efficiency thickener equipment, the slurry passes through the degassing device to remove most of the contained gas, and then enters the mixing device from the feeding pipe. The slurry is fully mixed with an appropriate amount of flocculant in the mixing device to form a good flocculation state, and then, It diffuses from its bottom to the surroundings and enters the pre-formed high-concentration sedimentation layer at the bottom of the thickening tank. At this time, the flocculated slurry (floc) settles to the bottom of the pool; the slurry water rises through the sedimentation layer. Here, the sedimentation layer plays a filtering role to prevent fine-particle sludge from rising. The slurry that has not been fully flocculated will continue to contact the flocs when it reaches the sedimentation layer so that the flocs will continue to grow. Finally, the rake frame is driven by the central drive device to push the concentrated material to the central discharge port and discharge the slurry water from the overflow port.

Features of high-efficiency thickener for sale:

1. It is equipped with a slow flow device to slow down the rising speed of the material flow so that the overflow water is more uniform and the turbidity is lower.

2. The addition of flocculant in the ore thickener increases the particle size of the settled solid particles and increases the settling speed.

3. The processing capacity is large, and the production capacity can reach 3400 t/d, which saves energy consumption by 30% compared with traditional thickeners.

4. It is equipped with a material receiving tray, and the feeding barrel is moved down, so that the fed ore slurry falls evenly and steadily, effectively preventing the phenomenon of turning over.

5. The high-efficiency thickener machine is equipped with an internal overflow weir to make the material flow according to regulations, prevent the "short circuit" phenomenon, and greatly increase the sedimentation area.

6. Equipped with complete automatic control facilities, easy to operate.

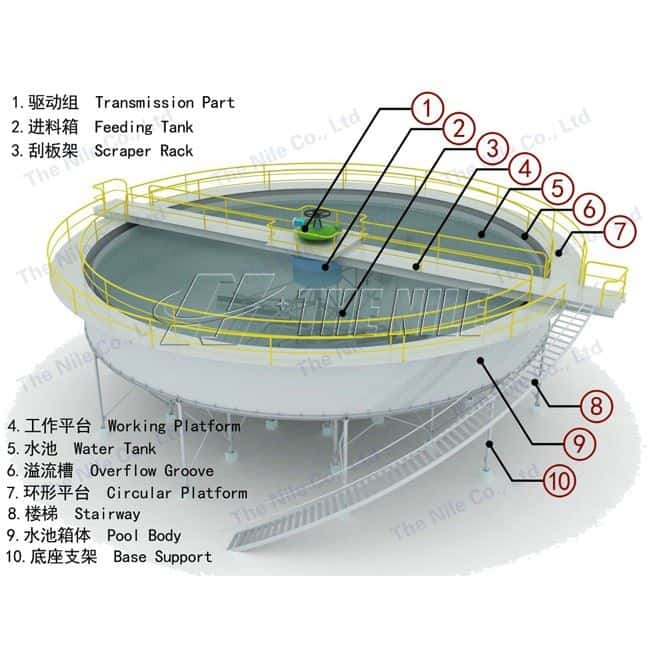

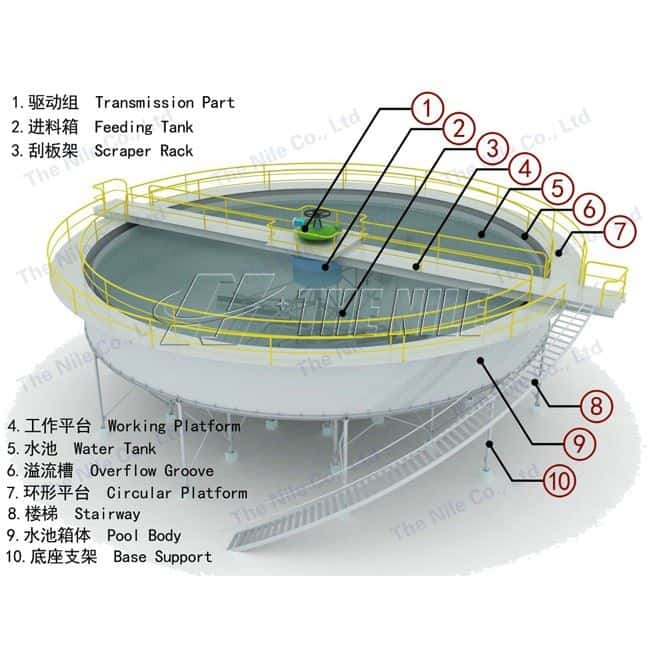

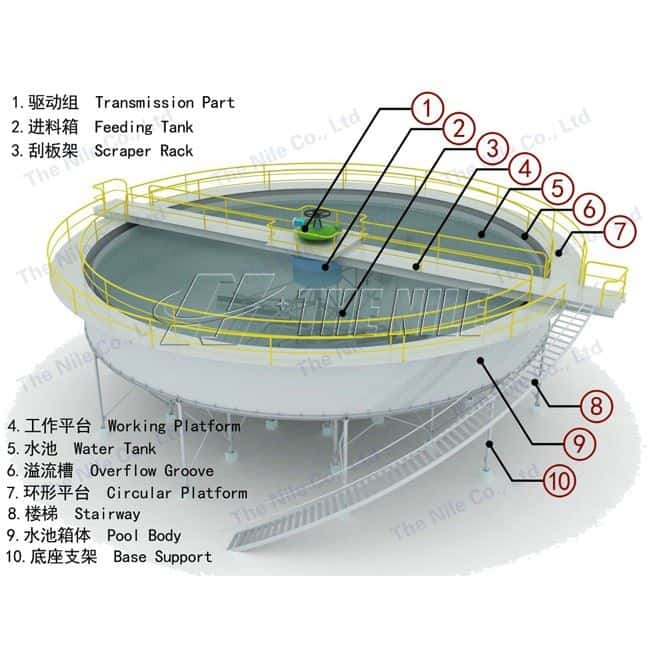

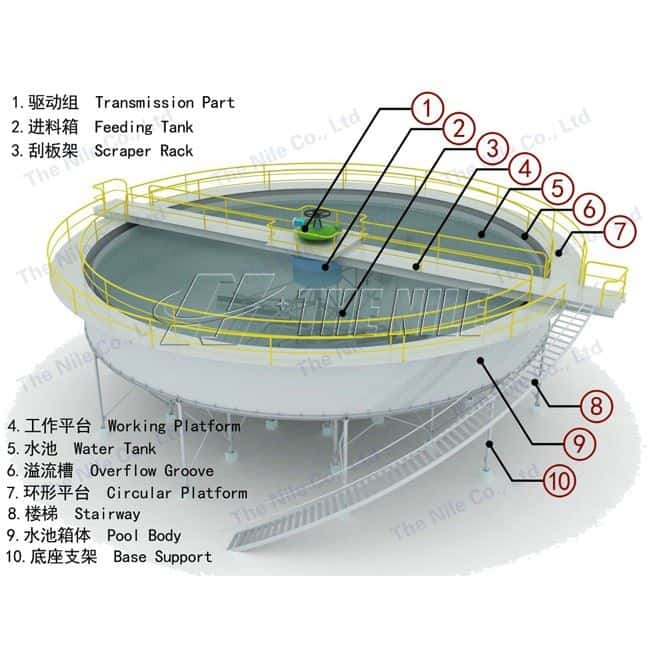

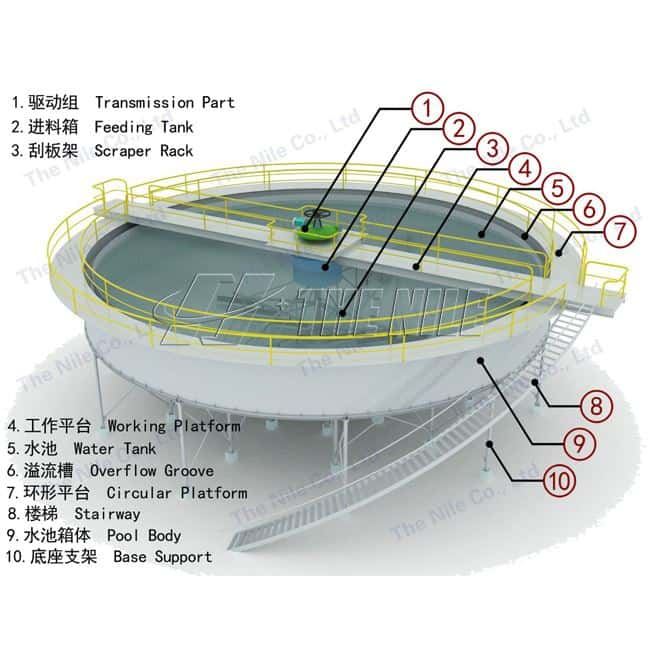

The structure of the thickener machine:

The efficient thickener is mainly composed of a thickening tank, a raked frame, a transmission device, a raked frame lifting device, a feeding device, a discharging device, and a signal safety device.

FAQ:

Q1: Do you provide equipment operation training?

A: Yes. We can send professional engineers to the work site for equipment installation, commissioning, and operation training. All our engineers have passports.

Q2: How is the quality of your products?

A: Our products are manufactured in strict accordance with national and international standards, and we will test every device before shipment. We guarantee that if the quality of the product is different from the description we described before you place the order, we promise a 100% refund.

Q3: Is the price of the product reliable?

A: Yes, we are a manufacturer, and we have the strength to provide you with the lowest price compared to other distributors. However, our policy is "according to the order quantity, we will provide the lowest possible price with an absolutely honest business attitude".

Company strength:

The Nile Machinery Company has a professional technical team and a strong business team, focusing on the research and development of stone crushing equipment, sand-making equipment, mineral ore beneficiation equipment, gold beneficiation equipment, and other equipment. The products are sold at home and abroad, and overseas warehouses have been established in Kenya and Sudan. You can observe the product up close, which is convenient and quick.

Overseas service:

1. We have engineers in Kenya, Sudan, and Uganda, they will provide professional installation and training skills.

2. We have factories and warehouses in Kenya and China. When your wearing parts are damaged, you can go directly to the factory to buy them, which is convenient and quick.

3. Our products have been distributed all over China and exported to Europe, America, Asia, and African countries. Our sales managers and engineers know the local situation very well, and we will provide you with the most suitable solution.

Client feedback:

Under the introduction of a friend, I purchased two high-efficiency thickeners in the Nile Machinery Company to concentrate gold mines. The equipment not only has high concentration efficiency but also has a large processing capacity. I am very satisfied with the effect after concentration. It is a very good shopping experience. I look forward to the next cooperation!

| Model | Transmission form | Concentration tank | Capacity(t/d) | Motor | Weight(kg) | |

| Diameter(m) | Depth(m) | Power(kW) | ||||

| NZS-1 | Centre drive | 1.8 | 1.8 | 5.6 | 1.1 | 1300 |

| NZS-3 | Centre drive | 3.6 | 1.8 | 22.4 | 1.1 | 2975 |

| NZS-6 | Centre drive | 6 | 3 | 62 | 3 | 8700 |

| NZS-9 | Centre drive | 9 | 3 | 140 | 3 | 16682 |

| NZS-12 | Centre drive | 12 | 3.5 | 250 | 3 | 33131 |

| NG-15 | Rollers | 15 | 3.5 | 390 | 5.5 | 9120 |

| NG-18 | Rollers | 18 | 3.5 | 560 | 5.5 | 10000 |

| NG-24 | Rollers | 24 | 3.7 | 1000 | 7.5 | 24000 |

| NG-30 | Rollers | 30 | 3.6 | 1570 | 7.5 | 26420 |

| NT-15 | Rack gear | 15 | 3.5 | 390 | 5.5 | 1100 |

| NT-18 | Rack gear | 18 | 3.5 | 560 | 5.5 | 12120 |

| NT-24 | Rack gear | 24 | 3.7 | 1000 | 7.5 | 28270 |

| NT-30 | Rack gear | 30 | 3.6 | 1570 | 7.5 | 30888 |

| NT-45 | Rack gear | 45 | 5.1 | 2400 | 11 | 58640 |

| NT-50 | Rack gear | 50 | 4.5 | 3000 | 11 | 65920 |

| NT-53 | Rack gear | 53 | 5.1 | 3400 | 11 | 69410 |