Applicable materials: granite, marble, basalt, limestone, quartz stone, river pebble, copper ore, iron ore, etc.

Product description:

GZD vibrating feeder is also called stainless steel vibrating feeder. In the production process, the vibrating feeder can feed block and granular materials from the storage bin to the receiving device uniformly, quantitatively, and continuously. In the sand and gravel production line, it can continuously and evenly feed the crushing machinery. It can also coarsely screen materials and is widely used in combined crushing and screening operations in metallurgy, coal mines, mineral processing, building materials, chemicals, abrasives, and other industries.

The working principle of vibrating feeder for mine

The motor drives the driving shaft through the V-belt, and the gear on the driving shaft meshes with the driven shaft to rotate. The driving shaft and the driven shaft rotate in opposite directions at the same time, so that the tank vibrates and the material flows continuously to achieve the purpose of conveying materials.

Features of GZD series vibrating feeder machine

Features of GZD series vibrating feeder machine

1. Simple structure and convenient maintenance

2. Uniform feeding, good continuous performance, the adjustable excitation force

3. The eccentric block of the vibrating conveyor feeder is used as the vibration source, with low noise, low power consumption, and no punching phenomenon.

4. The vibrating feeder can carry out coarse screening. At the same time as feeding, the role of bar or sieve plate is used to remove soil and fine materials to achieve the purpose of primary screening.

5. Low noise, which is conducive to improving the working environment

6. Strong adaptability. It has strong adaptability to various ore rocks, especially viscous ore materials, and can work in dusty or water-rich environments.

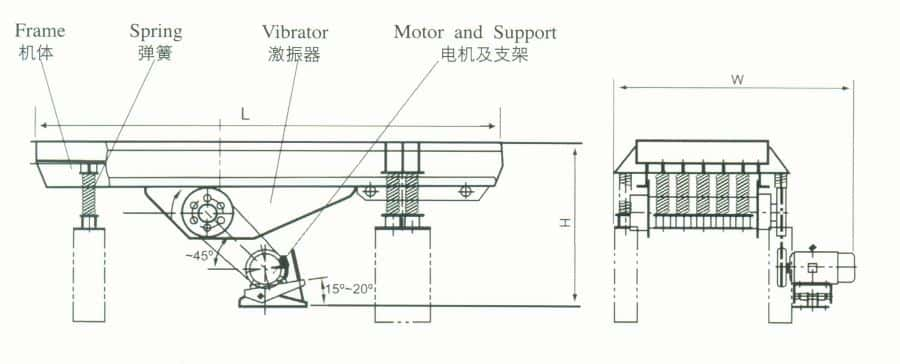

The structure of the stone vibrating feeder

GZD series vibrating magnetic feeder is composed of feeding trough, vibration exciter, spring support, transmission device, and so on. The vibration source of the trough vibration feed is a vibration exciter, which is composed of two eccentric shafts (active and passive) and a gear pair.

Vibration feeder equipment production process:

Company strength

The Nile Machinery Co., Ltd. is committed to designing various types of equipment such as stone crushing equipment, gold beneficiation equipment, mineral ore beneficiation equipment, and sand making equipment, which are widely used in electric power, metallurgy, mining, quarry, and other industries. The products are exported to all parts of the world, especially in Europe, America, Asia, and Africa, and are well received by customers. At present, The Nile has its own overseas warehouses in Kenya and Sudan, and customers can observe the machines up close and purchase them.

Packaging and shipping:

Customer case:

Project case: 300 tons of fine aggregate production line per hour

Output: 300 t/h

Configuration equipment: a GZD vibrating feeder 1500*6000, a jaw crusher PE1000*1200, two impact crushers PF1315, a circular vibrating screen 2YK2460, and other auxiliary equipment.

Product details: A mine owner from Sudan found the Nile and said that he wanted a 300 t/h fine aggregate production line. After receiving this news, our company's technical department immediately began to make plans for customers. According to various considerations and on-site exploration, the customer was finally equipped with a GZD feeder 1500*6000, a jaw crusher PE1000*1200, two impact crushers PF1315, a circular vibrating screen 2YK2460, and other auxiliary equipment.

| Model | Feeding size | Capacity | Power | Weight | Dimension |

| (mm) | (t/h) | (kW) | (t) | (m) | |

| GZD850*3000 | ≤400 | 40-100 | 7.5 | 3.9 | 3.1*1.79*1.61 |

| GZD960*3800 | ≤500 | 120-210 | 11 | 4.22 | 3.84*1.96*1.62 |

| GZD1100*4200 | ≤600 | 150-350 | 15 | 4.68 | 4.38*2.1*1.67 |

| HZD1300*4900 | ≤750 | 350-530 | 22 | 6.2 | 5.2*2.37*1.72 |

| HZD1500*6000 | ≤800 | 450-810 | 30-45 | 10.3 | 6.16*2.918*2.292 |