The Mobile Jaw Crusher Station also named portable crusher station, is a new type of crushing equipment, researched and designed by our experienced engineers. It is widely used in mines, coal mines, garbage and construction waste recycling, civil engineering, urban infrastructure, roads or construction sites and so on.

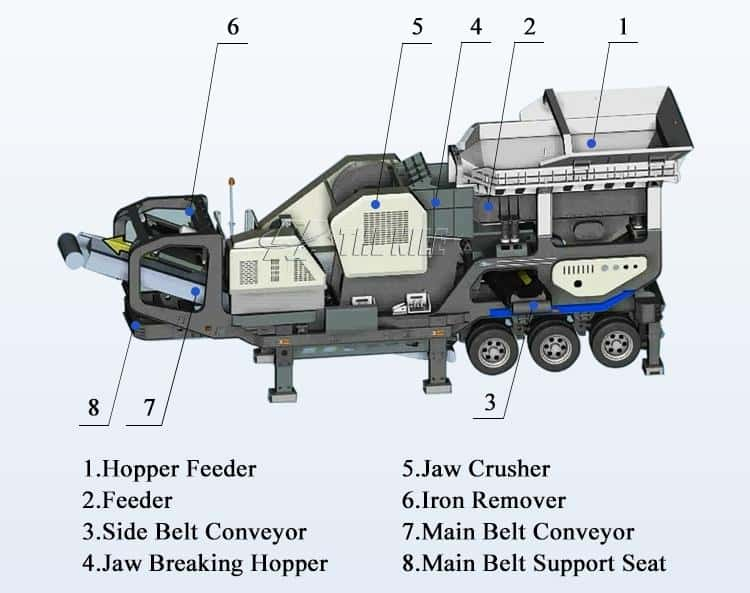

Product Description The Mobile Jaw Crusher Station also named portable crusher station, is a new type of crushing equipment, researched and designed by our experienced engineers. It is widely used in mines, coal mines, garbage and construction waste recycling, civil engineering, urban infrastructure, roads or construction sitesand so on. In addition, the Mobile Jaw Crusher Stationis mainly composed of feeder, jaw crusher and belt conveyor, with the capacity of85-650 tons per hour.It adopts the integrated group operation mode, which can work separately, eliminates the complex site infrastructure and auxiliary facilities installation of the split-component, and reduces the man-hour consumptionas well.What’s more, the Mobile Jaw Crusher Station has the outstanding advantages of long service life, easy operation, long service life, advanced technology, high efficiency, low failure rate, impact resistance as well as high cost effective. It is very popular with our clients worldwide due to high performance. |

Main Features 1. Move easily. It can go to the crushing place directly. It can move not only on the smooth road, but also on the bumpy road. 2. Compact structure and simple operation. Integrative equipment group with trailer save the working area. With generator, motor and control box on the trailer, it can work outdoor easily. Equipped with supporting facilities, it can be installed quickly and conveniently. 3. Operating system with imported direct servo technique can be easily and precisely controlled and travel in a high speed. |

Certificate

Our Service ● Pre-sales service: We provide you with prophase plan, process flow design and manufacturer equipment according to your special needs. ● Sales service: Send technicians to your site guiding the installation and adjustment, training operators and finishing the check and accept together with you. ● After-sales service: To establish long term friendship, we will pay return visit to customers. Supplying technique, building design, instruction, installation and debugging for free. ● Lifelong service: One year warranty to make sure your machine runs constantly.Always offer lifelong service and provide spare parts for a long term. |

Mobile jaw crusher plant | PP600 | PP750 | PP900 | PP1060 | PP1200 | PP1300PEX | |

Crusher plant size | Length(m) | 8.6 | 9.6 | 11.1 | 13.3 | 15.8 | 9.4 |

Width(m) | 2.5 | 2.5 | 3.8 | 2.9 | 2.9 | 2.7 | |

Height(m) | 3.8 | 3.5 | 3.5 | 4.4 | 4.5 | 4.0 | |

Jaw crusher | Feed size(mm) | 340 | 425 | 500 | 630 | 750 | 250 |

Output size(mm) | 40-100 | 50-100 | 65-160 | 230-290 | 195-265 | 20-90 | |

Capacity(t/h) | 16-60 | 40-110 | 50-180 | 230-290 | 315-500 | 16-105 | |

Motor power(kw) | 30 | 55 | 75 | 90 | 160 | 55 | |

Vibrating feeder | Capacity(m3/h) | 10-35 | 25-60 | 30-85 | 70-150 | 100-240 | 10-60 |

cubage(m3/h) | 3 | 4 | 7 | 10 | 10 | 3 | |

Width(mm) | 2200 | 2500 | 3000 | 3000 | 3000 | 2200 | |

Conveyor belt | Width(mm) | 400 | 500 | 500 | 650 | 800 | 500 |

Speed(m/s) | 0.8-2 | 0.8-2 | 0.8-2 | 0.8-2 | 1.0-2 | 0.8-2 | |