The wheel sand washing machine has reasonable structure, convenient maintenance, large processing capacity, small power consumption and high washing degree, suitable for washing of fine-grained and coarse-grained materials.

High efficiency wheel sand washing machine Wheel sand washing machine is widely used in washing, grading impurity removal in metallurgy, building materials, other industries. It is suitable for washing of fine-grained and coarse-grained materials for construction and road construction. The wheel sand washing machine has reasonable structure, convenient maintenance, large processing capacity, small power consumption and high washing degree. |

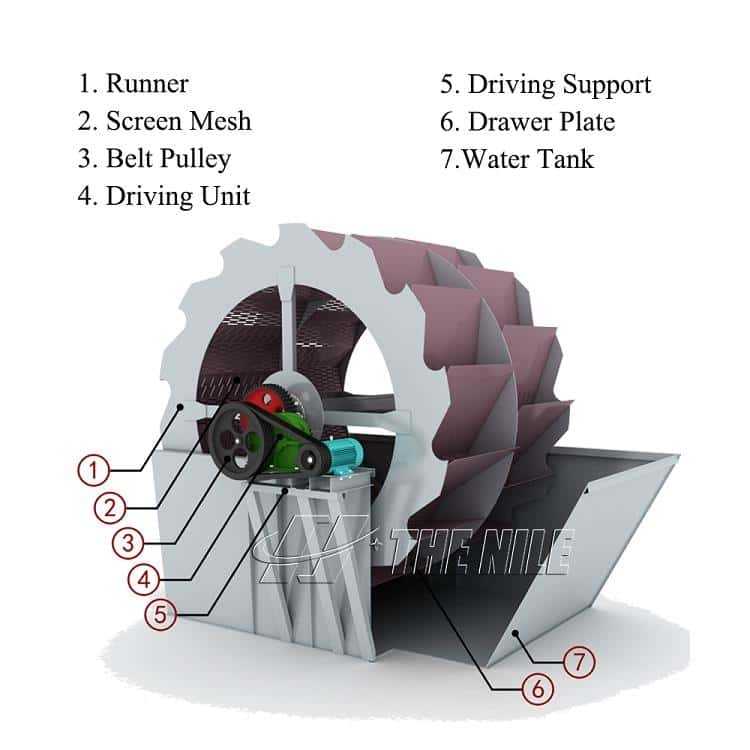

| The novel sealing structure, fully enclosed oil bath transmission and adjustable overflow weir plate ensure the high efficiency and durability of the series, good cleaning and dewatering effect, and stable stability of fine grain products. |

Working Principle The electric motor runs slowly with the impellor after decelerated by the belt, decelerator and gears wheel. The sand and stone flow into washing launder from feeding launder, rolls with the impellor, and grinds each other. The impurity covering the sand is washing away. At the same time, add more water, the strong water flow will take away waste and some low-weight wastes from washing launder. Through the above process, the washing function is finished. The clean sand and stone is lift up by vane. When it goes up slowly, the water begins to drop through the mesh and fall back in the washing launder. On one hand, water is removed from the sand and stone; on the other hand, the water can be fully used. Finally, the sand and stone goes to the out launder from the rotary impellor to finish the washing task. |

Main Features

1. Reasonable structure.

2. Large capacity.

3. Low consumption.

4. Little loss of the sand during the washing process.

5. Low failure rate.

Details

Packing&Shipping

FAQ Q1: Are you factory or trade company? A1: We are factory. Q2: Where your products have been exported before? A2: Our products have been sold to South Asia, Africa, South America, middle East and so on. Q3: How will you help the customer to install the equipment? A3: Our senior engineer will guide the installation and commissioning as well as the initial production at Q4: How about the wear parts supply? A4: We offer wear parts to our customer with our most favorable price. If there are problems youcould not handle, we will send our technicians to your place and you are therefore, responsible for all thecost involved. Q5: What about the payment method? A5: T/T, L/C Paypal is available |

Our Service ● Pre-sales service: We provide you with prophase plan, process flow design and manufacturer equipment according to your special needs. ● Sales service: Send technicians to your site guiding the installation and adjustment, training operators and finishing the check and accept together with you. ● After-sales service: To establish long term friendship, we will pay return visit to customers. Supplying technique, building design, instruction, installation and debugging for free. ● Lifelong service: One year warranty to make sure your machine runs constantly.Always offer lifelong service and provide spare parts for a long term. |

Model | XS2300 | XS2600 | XS2900 | XS3500 |

Bucket diameter(mm) | 2300 | 2600 | 2900 | 3500 |

Rotation speed(r/min) | 1-2 | 1-2 | 0.8-1.5 | 0.8-1.2 |

Capacity(t/h) | 15-30 | 20-50 | 50-100 | 120-200 |

Power(kw) | 4 | 5.5 | 7.5 | 11 |

Weight(kg) | 4300 | 5600 | 8100 | 9900 |

Dimension(m) | 3.15*1.91*2.69 | 3.52*2.39*2.69 | 3.82*2.64*3.2 | 4.42*2.93*3.8 |