Fine Sand Recycling Machine is widely used in fine sand mud purification, hydropower stations aggregate processing system, glass raw materials handling system, artificial sand production line, coarse coal slime recovery and environmental engineering, etc.

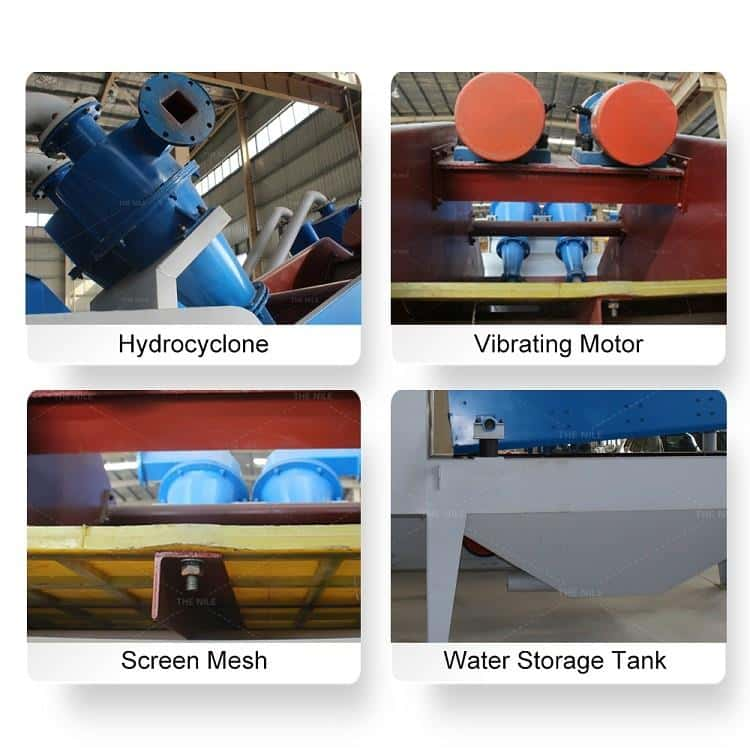

Product Description This kind of Fine Sand Recycling Machineis a new type environmental protection equipment whichhas been researched and developed by absorbing advanced foreign technology. It is widely used in fine sand mud purification, hydropower stations aggregate processing system, glass raw materials handling system, artificial sand production line, coarse coal slime recovery and environmental engineering,etc., which has effectively solved fine sand recovery problem. In addition, the Fine Sand Recycling Machine uses the latest type of vacuum high-pressure pump, with dynamic pressure reduction, efficient sealing,soslurry is not easy to leak. The vibrating screen uses a polyurethane screen,which has a longer life than other types of screens on the market and does not block holes.The Fine Sand Recycling Machine also has the properties of delicate design, compact structure, high efficiency, easy operation, simple maintenance as well as durability. |

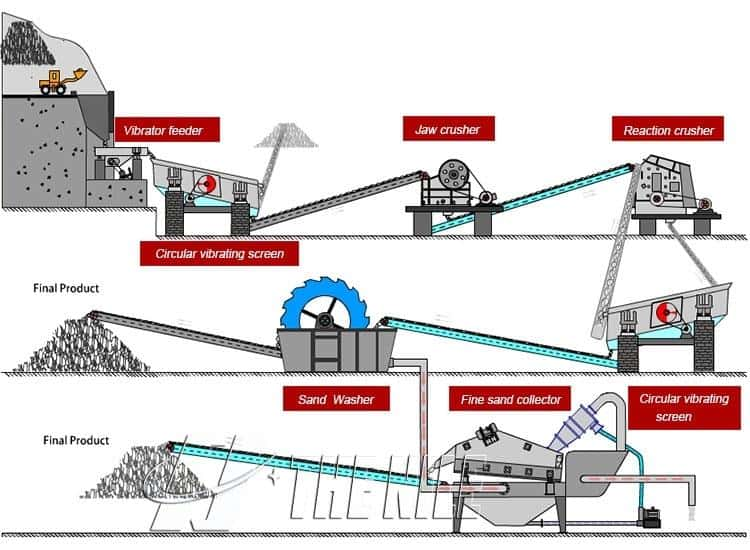

Working Principle Working process: The pump sends the sand and water mixture to cyclone, the fine sand with eccentricity is sent to vibrating screen. The fine sand and water are effectively separated after dehydration, and little fine sand and mud go back to washing trough. When the liquid surface of the washing trough is high, the fine sand discharges from output opening. The linear vibrating screen can recover material with concentration 70%-85%, and fineness adjustable is achieved by changing pump rotation speed, changing mortar concentration, and adjusting overflow water yield. |

Main Features 1. Effectively reduce the fine sand losing quantity, and make it in the scope of 5-10%. 2. Inner the polyurethane, strengthen the whole device service life, it can smoothly finished the work of condensing slime and clearing the liquid etc. 3. The maximum fine grain materials quantity recovered from the total effluent is 95%, so it has unsurpassed technology and economic advantage compared with other equipments. 4. The find sand are recovered sufficiently, you can reduce the sedimentation basin workload and Low its clean cost. 5. Reducing nature stock time of the fine material, they can be transferred directly and supplied to the market. 6. We can design corresponding solve project according to our consumers, different requirements. |

Details

Packing&Shipping

A standard package in wooden boxes or containers

FAQ Q1: Are you factory or trade company? A1: We are factory. Q2: Where your products have been exported before? A2: Our products have been sold to South Asia, Africa, South America, middle East and so on. Q3: How will you help the customer to install the equipment? A3: Our senior engineer will guide the installation and commissioning as well as the initial production at Q4: How about the wear parts supply? A4: We offer wear parts to our customer with our most favorable price. If there are problems youcould not handle, we will send our technicians to your place and you are therefore, responsible for all thecost involved. Q5: What about the payment method? A5: T/T, L/C Paypal is available Q6: What about after-sale service? A6:12 months warranty for all kinds of products. |

Model | Hydrocyclone | Capacity | Pump | Dewatering screen | Weighy | |||

Power(kw) | Dimension | Model | Area(m3) | Power(kw) | ||||

06-300 | 2*300 | 30-80 | 11 | 2.5" | 0.6*2.25 | 1.35 | 2*0.55 | 3945 |

08-300 | 2*300 | 40-100 | 15 | 3" | 0.8*2.25 | 1.8 | 2*0.75 | 4200 |

10-350 | 2*350 | 70-130 | 18.5 | 3" | 1.0*2.25 | 2.25 | 2*0.75 | 4900 |

12-500 | 2*500 | 100-220 | 22 | 4" | 1.2*3.0 | 3.6 | 2*1.1 | 7515 |

12-650 | 2*650 | 120-272 | 30 | 5" | 1.2*3.0 | 3.6 | 2*1.1 | 7833 |

14-750 | 2*750 | 180-350 | 37 | 6" | 1.4*3.75 | 4.2 | 2*1.1 | 9610 |

14-750II | 2*750 | 230-430 | 45 | 6" | 1.4*3.75 | 5.25 | 2*1.5 | 11850 |

16-900 | 2*900 | 250-500 | 55 | 8" | 1.6*3.75 | 6.00 | 2*1.5 | 14300 |