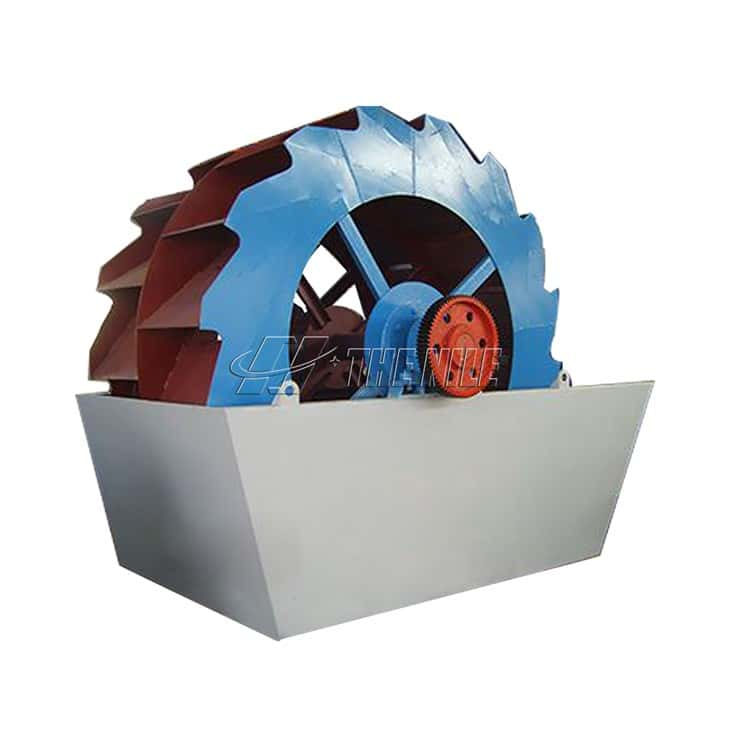

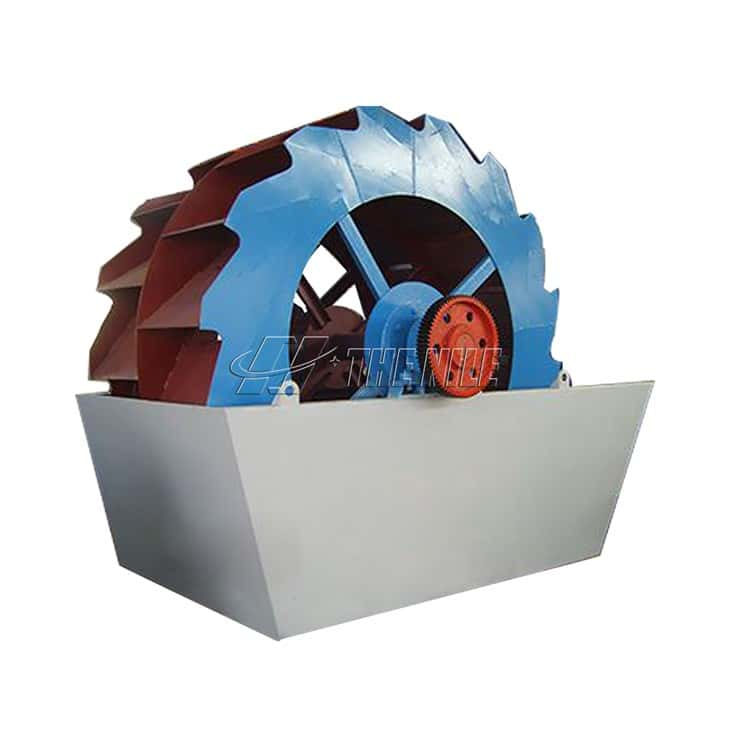

Applied Field: Sand washing machine is widely applied in the washing, grading and metallurgy, building materials, hydropower, highways, mine sand making, impurity removal, and other industries., especially for the washing operation of fine and coarse-grained materials. The sand washing machine is suitable for construction sand and gravel for road construction.

Working Principle of Sand Washing Machine

When working, the motor drives the impeller to rotate slowly through the V-belt, reducer, and gear of sand washing machine. The sand and gravel enter the washing tank through the feeding trough, roll under the impeller, grind each other to remove the impurities covering the surface of the gravel and destroy the water vapor layer covering the sand particles. At the same time, water is added into the sand making machine to form a strong water flow to take away impurities and foreign matters with small specific gravity by discharging from the overflow outlet. The clean sands are taken away by the blade and poured into the discharge tank from the rotating impeller to complete the cleaning of sand and stone.

Performance Characteristicsof Sand Washing Machine

1.Due to the high cleaning height of the sand washing machine, the sand loss is less during the washing process, especially the transmission parts are isolated from water and sand, so the failure rate of the sand washing machines is much lower than that of the common sand washing machine.

2.The sand washing machine has a Reasonable structure, novel sealing structure, fully enclosed oil bath type transmission device and an adjustable overflow weir plate, which ensures that the high efficiency and durability of the sand washer, good cleaning and dewatering effect, and stable fine-grained products.

3.Long service life,withoutmaintenance for a long time.

4.Water saving, pollution-free and durable.

Model | XS2300 | XS2600 | XS2900 | XS3500 |

Bucket diameter(mm) | 2300 | 2600 | 2900 | 3500 |

Rotation speed(r/min) | 1-2 | 1-2 | 0.8-1.5 | 0.8-1.2 |

Capacity(t/h) | 15-30 | 20-50 | 50-100 | 120-200 |

Power(kw) | 4 | 5.5 | 7.5 | 11 |

Weight(kg) | 4300 | 5600 | 8100 | 9900 |

Dimension(m) | 3.15*1.91*2.69 | 3.52*2.39*2.69 | 3.82*2.64*3.2 | 4.42*2.93*3.8 |