The VSI sand-making machine can make all kinds of rocks, gravel, and river pebbles into construction sand with various particle sizes, with uniform sand density and high compressive strength.

Product Introduction

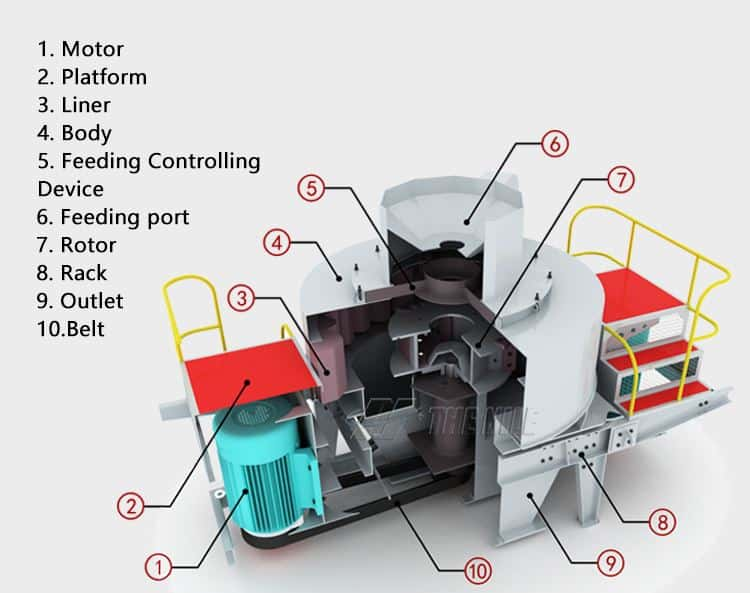

Sand-making machine, also known as impact crusher, is a high-efficiency and high-quality sand-making equipment developed by using the principle and technology of foreign "stone-on-rock" crushers and combining with the actual situation of domestic sand production. The new VSI sand maker machine is widely used in highways, high-speed railways, high-rise buildings, municipal administration, hydroelectric dam construction, concrete mixing stations to provide high-quality sand and gravel aggregates, and is equipped in the field of artificial sand making and stone shaping.

Working principle:

In the working process of the sand-making equipment, the material enters the machine from the hopper, and the material is divided into two parts by the distributor. One part enters the high-speed rotating impeller from the middle of the distributor and is rapidly accelerated in the impeller. The impeller is ejected from the three evenly distributed channels. First, it is impacted and crushed with a part of the material that has been collected from the divider. Then, it impacts the material lining in the vortex cavity. The top of the vortex cavity changes its direction of movement and deflects to move downward, and the material emitted from the impeller runner forms a continuous material curtain. Such a piece of material is subjected to two or more times of probability impact, friction and grinding and crushing in the vortex crushing cavity, and the crushed material is discharged from the lower discharge port.

Product advantages:

1. Various crushing standards

The sand-making machineadopts the "stone-on-rock" crushing principle, and the combined throwing head will automatically replace the good throwing head after the parts are worn, which helps to save costs.

2. Good particle size of the finished product

The VSI sand-making machinefunctionhas the controllability of rough grinding and fine grinding, and the particle size of materials, and has a certain shaping effect. The finished sand has a good grain shape, reasonable gradation, and adjustable fineness modulus.

3. Saving and environmental protection

The airflow in the vortex cavity of the sand-making equipment is self-circulating, with less dust and low noise during work. At the same time, the brand motor is selected, which has sufficient kinetic energy and more energy saving.

4. Durable

During the production processof the sand maker equipment, the base can form a protective bottom layer, the machine body is wear-free and durable.

5. Large processing capacity and high output

The VSI stone-makingmachine can process materials of 50-500t/h. Compared with the traditional equipment under the same power, the output is increased by 30% and is stable and reliable.

FAQ

Q: Do you have warehouses abroad?

A: Yes, there are warehouses in Sudan and Kenya, and there are agencies in other places, you can buy with confidence.

Q: Are your prices expensive?

A: Not expensive, we are direct sales from the factory, and we can guarantee that you can buy the highest quality equipment at the lowest price.

Q: How is your machine packaged and shipped?

A: We uniformly use plastic film to seal and put them in a container for transportation, which is convenient for transportation and not easy to damage.

| Model No. | VSI7611 | VSI8518 | VSI9526 | VSI1140 | VSI1145 | |

| Capacity | Cascade Feeding | 120-180 | 200-260 | 300-380 | 450-520 | 500-640 |

| (t/h) | Full Central Feeding | 60-90 | 100-130 | 150-190 | 225-260 | 250-360 |

| Max. Feeding size(mm) | Soft Material | 35 | 40 | 45 | 50 | 50 |

| Hard Material | 30 | 35 | 40 | 45 | 45 | |

| Rotation Speed (r/min) | 1700-1890 | 1520-1690 | 1360-1510 | 1180-1310 | 1100-1310 | |

| Model of Motor | Y250M-4 | Y280M-4 | Y315M-4 | Y315L2-4 | Y315L2-4 | |

| Double Motor Power | 55*2 | 90*2 | 132*2 | 200*2 | 220*2 | |

| Weight (t) | 10 | 12 | 16 | 25.6 | 27.5 | |