Applied Field: Sand maker machine is widely used in the medium and fine crushing of high-hard and extra-hard materials such as various ore, cement, refractory materials, bauxite clinker, emery, and glass raw materials, especially used in the crushing of machine-made building sand, stone and various metallurgical slags.

Introduction of Sand Maker Machine

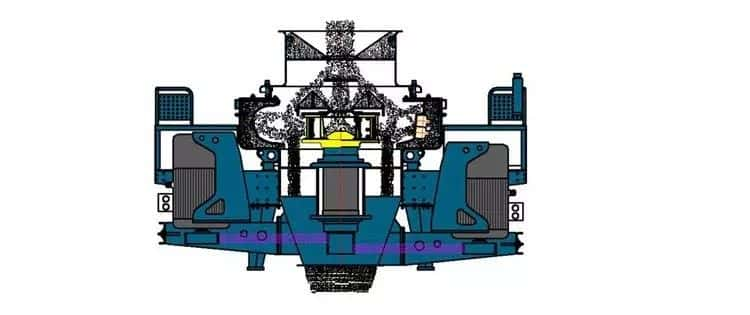

Sand maker machine uses the stone-to-stone principle and has fine crushing and coarse grinding functions with low abrasion, high crushing rate, energy-saving, and less affected by the moisture content of the material. The moisture content can reach about 8% and working noise is less than 75 decibels (db level), which has less dust pollution and suitable for crushing medium-hard and extra-hard materials. The finished products are cubes with high bulk density, minimal iron pollution, low wear of the impeller self-lining, and easy maintenance.

Operating Procedures of Sand Maker Machine

1.Before the start-up of the sand maker machine, check whether the observation door of the vortex chamber is closed tightly, so as to prevent materials from rushing out of the observation door of the whirling chamber and causing danger.

2.Check the rotation direction of the impeller from the direction of the feed inlet. The impeller should rotate anticlockwise, otherwise, the motor wiring of the sand maker machine should be adjusted.

3.The starting sequence of sand crusher and conveying equipment is: discharging → crusher → feeding.

4.The sand maker machine must be started with no-load and fed after the crusher operates normally.The stopping sequence of equipment is opposite to the starting sequence.

5.When the discharging equipment stops, the feeding should be stopped in time, otherwise, the impeller will be crushed and the motor will be burned.

6.Feeding of the sand maker machine should be continuous and even.

7.During the operation of the sand maker machine, there shall be no severe vibration and abnormal noise, otherwise, the equipment shall be stopped for inspection.

8.The lubrication of the machine is dry oil lubrication and the amount added is 1/2-2/3 of the bearing cavity. When the sand maker machine works every shift, add an appropriate amount of grease to work several. After several shifts, open and clean the main bearing and replace the bearing if necessary.

Technical Parameters of Sand Maker Machine

Model No. | VSI7611 | VSI8518 | VSI9526 | VSI1140 | VSI1145 | |

Capacity | Cascade Feeding | 120-180 | 200-260 | 300-380 | 450-520 | 500-640 |

Full Central Feeding | 60-90 | 100-130 | 150-190 | 225-260 | 250-360 | |

Max. Feeding size(mm) | Soft Material | 35 | 40 | 45 | 50 | 50 |

Hard Material | 30 | 35 | 40 | 45 | 45 | |

Rotation Speed (r/min) | 1700-1890 | 1520-1690 | 1360-1510 | 1180-1310 | 1100-1310 | |

Model of Motor | Y250M-4 | Y280M-4 | Y315M-4 | Y315L2-4 | Y315L2-4 | |

Double Motor Power | 55*2 | 90*2 | 132*2 | 200*2 | 220*2 | |

Weight (t) | 10 | 12 | 16 | 25.6 | 27.5 | |