Applied Field: Washed sand is natural silica sand that has been washed and graded by silica sand washing process with a mud content (mass fraction) ≤1.0%. Silica sand washing process plant is widely applied in concrete construction, ceramics, refractory materials, smelting ferrosilicon, metallurgy, chemical industry, plastics, rubber, abrasives, and other industries.

Introduction of Silica Sand

Quartz and silica stone are called quartz sand and silica sand after being broken. Silica content above 98.5% is called quartzite, and silicon dioxide content below 98.5<98.5 is called silica. Quartz sand and silica sand are important industrial mineral raw materials, which are widely used in glass, casting, ceramics, refractory materials, metallurgy, construction, chemical industry, plastics, rubber, and other industries.

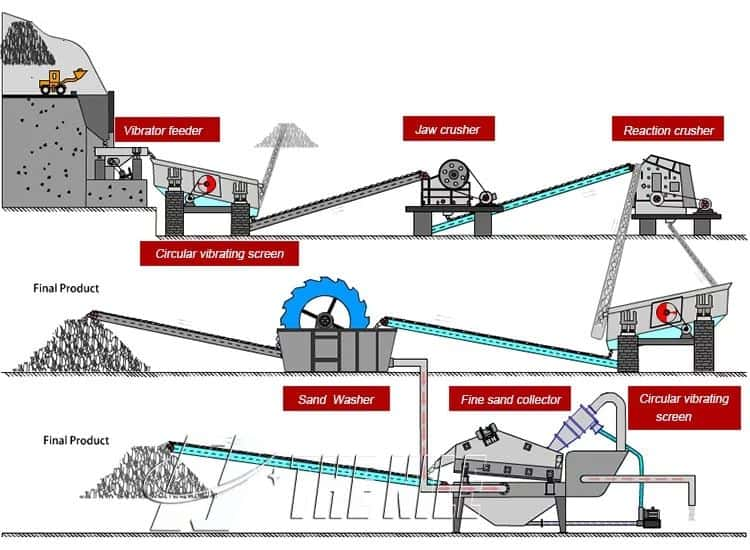

Work Flows of Silica Sand Washing Process

Silica sand washing process plant is composed of a silo, vibrating feeder, crusher, sand washer, fine sand recycling machine, vibrating screen, and other equipment. The silica sand is initially crushed by the jaw crusher. Then the produced coarse material is transported by belt conveyor to the cone crusher (or impact crusher) for further crushing. The fine crushed silica sand is screened into a vibrating screen to separate out two kinds of sand, the manufactured sand which meets the feeding size of the sand making machine is made into finished sand after being cleaned by the silica sand washing process machine, and unqualified silica sand continues to be crushed by the system until the finished material is produced. The finished materials need to be dried by drying machine or natural drying.

Model | XS2300 | XS2600 | XS2900 | XS3500 |

Bucket diameter(mm) | 2300 | 2600 | 2900 | 3500 |

Rotation speed(r/min) | 1-2 | 1-2 | 0.8-1.5 | 0.8-1.2 |

Capacity(t/h) | 15-30 | 20-50 | 50-100 | 120-200 |

Power(kw) | 4 | 5.5 | 7.5 | 11 |

Weight(kg) | 4300 | 5600 | 8100 | 9900 |

Dimension(m) | 3.15*1.91*2.69 | 3.52*2.39*2.69 | 3.82*2.64*3.2 | 4.42*2.93*3.8 |