Feeding size: 50-250 mm

Output: 1-200 t/h

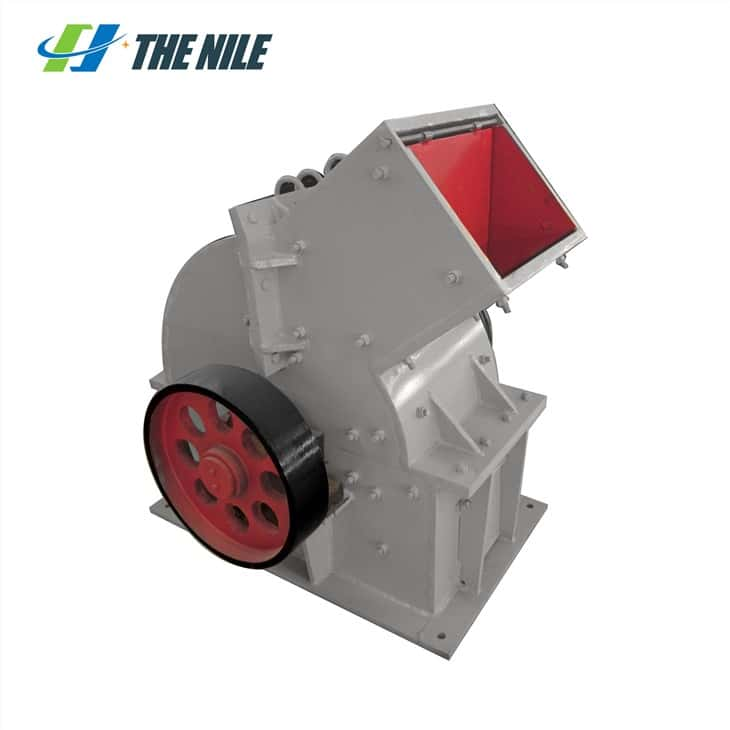

Product description:

Hammer crusher, also known as hammer rock crusher machine, has one-time molding, a large crushing ratio, high production capacity, and uniform product particle size. It is suitable for finely crushing limestone, coal, or other brittle materials below medium hardness in metallurgical, building materials, chemical industry, hydropower, and other industrial departments.

Working principle of hammer crusher for sale

The hammer crusher mainly crushes materials by impact. When the materials enter the crusher, they are crushed by the impact of the high-speed rotating hammer. The crushed materials obtain kinetic energy from the hammer and rush into the frame at high speed. At the same time, the baffle and the sieve bar collide with each other and are crushed many times. The materials smaller than the gap between the sieve bars are discharged from the gap, and individual larger materials are again impacted and ground by the hammer on the sieve bar. , Squeezed and broken, the material is squeezed out of the gap by the hammer, so as to obtain the product with the required particle size.

Features of hammer crushing machinery

1. The hammer head of the hammer rock crusher equipment is made of high-iron cast iron, which has strong wear resistance and long service life.

2. The work efficiency is high, the hammer rock crusher has a large processing capacity and low energy consumption.

3. The crushing ratio is large, the production capacity is high, the product is uniform, and the phenomenon of excessive powder is less.

4. Wide application range. The hammer crusher machine is suitable for a variety of medium hardness materials, such as limestone, coal, coke, and other materials with a compressive strength of less than 200Mpa. It is widely used in mining, smelting, building materials, highways, railways, water conservancy, and many other industries.

5. The hammer crusher equipment can adjust the gap between the grate bars and change the discharge particle size according to user requirements to meet the different needs of different users.

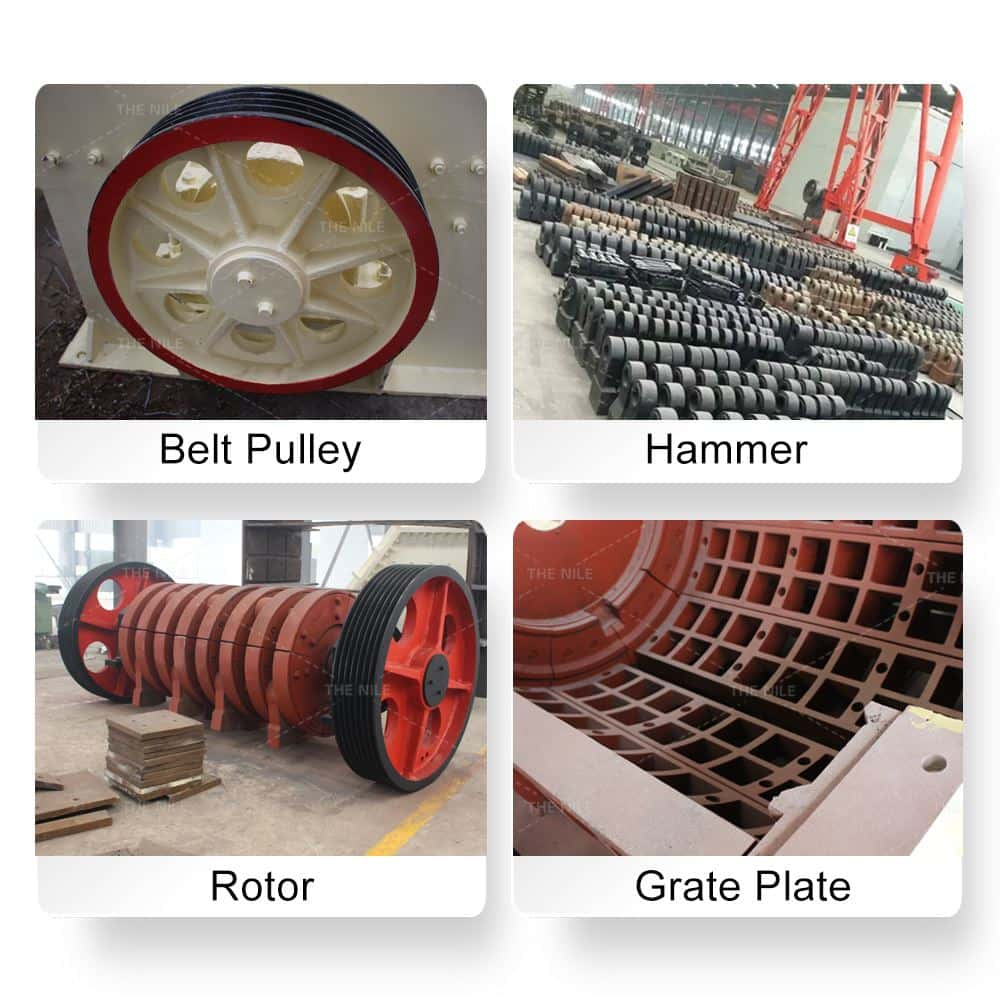

The structure of the mine stone hammer crusher

The hammer stone crusher machine is mainly composed of a box body, a rotor, the main shaft, a hammer head, a counterattack liner, and a sieve plate.

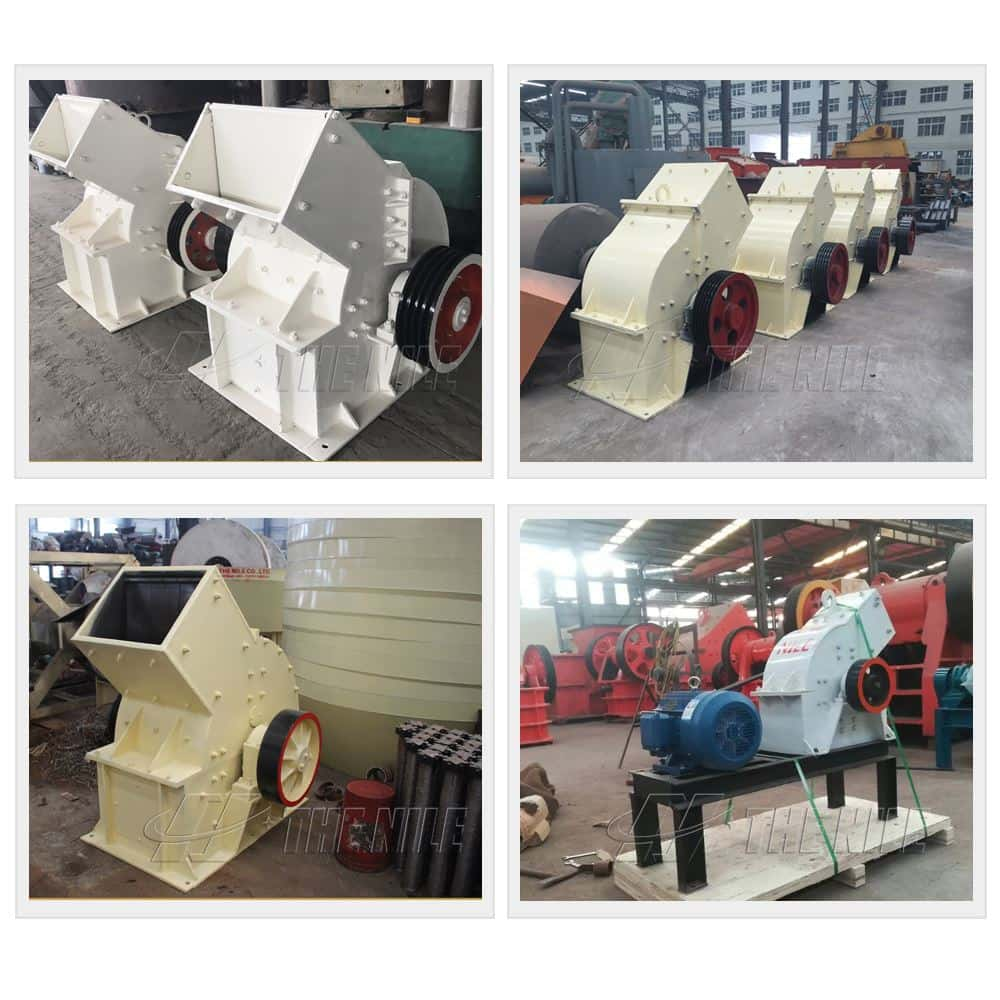

Packaging and transportation

Company strength

The Nile Machinery Equipment Co., Ltd. is a metallurgical machinery professional machinery factory that specializes in mining equipment research and development, manufacturing, sales, and provides professional mining processing plant workflow design, plant installation, equipment maintenance, and mineral processing technical guidance services. Our products are exported to Africa, Nigeria, Zambia, Zimbabwe, Uganda, Mozambique, South America, the Middle East, and many other countries and regions. At present, we have established our own overseas warehouses in Sudan and Kenya, and we also have our offices in most parts of Africa. You can observe the machinery up close and buy directly, saving transportation costs and time.

customer case

| Model No. | Max. Feeding Size | Output Size | Capacity | Motor Power | Weight |

| (mm) | (mm) | (t/h) | (kw) | (t) | |

| PC 300*200 | ≤50 | ≤10 | 1-2 | 5.5 | 0.4 |

| PC400*300 | ≤100 | ≤10 | 5-10 | 11 | 0.8 |

| PC600*400 | ≤120 | ≤15 | 10-25 | 22 | 1.5 |

| PC800*600 | ≤120 | ≤15 | 20-35 | 55 | 3.1 |

| PC1000*800 | ≤200 | ≤13 | 20-40 | 75 | 7.9 |

| PC1000*1000 | ≤200 | ≤15 | 30-80 | 90 | 8.65 |

| PC1200*1000 | ≤250 | ≤19 | 80-200 | 132 | 13.6 |